¶ Brief Overview

The Cold Pull is a specialized maintenance procedure used to effectively remove the maximum amount of filament and potential contaminants from the Vision Miner 22IDEX hotend and nozzle. It involves heating and then partially cooling filament within the hotend, then pulling it out in a semi-solid state. This guide explains when and how to perform a Cold Pull using the printer's built-in macro.

¶ Introduction

There are times when simply extruding or retracting filament isn't enough to clear the hotend effectively. A Cold Pull is the recommended method when:

- Changing Filament Types: Especially when switching between materials with different temperature requirements or colors, a Cold Pull minimizes cross-contamination.

- Cleaning the Nozzle: It's an excellent technique for removing small particles, debris, or partially burnt filament residue that might cause partial clogs or affect print quality.

This procedure utilizes the filament itself as a cleaning tool, pulling out residue as it is removed.

¶ Tools & Materials

- Filament:

- Recommended for Cleaning: Nylon (

PA6orPA12, without Carbon Fiber if possible) offers the best cleaning properties. - For Simple Removal: The filament currently loaded or the new filament type can also be used, but may be less effective at removing contaminants than Nylon.

- Recommended for Cleaning: Nylon (

- Wire Cutters: To create a clean tip on the filament for loading.

¶ Safety & Pre-checks

Warning: The hotend will reach high temperatures during the initial phase of this procedure. Avoid touching the nozzle or heater block.

- Ensure you have the filament you intend to use for the Cold Pull ready.

¶ Step-by-Step Instructions

¶ 1. Purpose and Material Selection

- When to Use: Use the Cold Pull procedure when switching between significantly different filament types (e.g., PLA to PEEK, PETG to Nylon) or as a first step in troubleshooting partial clogs or extrusion inconsistencies.

- Material Choice: For the most effective cleaning, using a spool of clean

Nylon(likePA6orPA12, preferably without carbon fiber additives) is highly recommended. Its properties allow it to grab onto contaminants effectively. If simply removing the current filament is the goal, you can often use the same filament or the next type you plan to load. You will need to know the approximate correct heating temperature for the filament you choose.

¶ 2. Prepare and Load Filament

- Prepare Tip: Cut the end of the filament you will use for the Cold Pull at a clean angle using Wire Cutters.

- Load Filament: Manually load this filament into the specific toolhead (T0 or T1) you wish to clean. Feed it through the extruder until you feel it reach the gears.

The filament loading process is described in more detail Here

- Heat up Toolhead: In the tool's status area, enter the appropriate printing temperature for your filament (refer to manufacturer recommendations) and click Set, or select a pre-defined material. Wait for the nozzle to reach the target temperature.

- Extrude Filament: Go to

Dashboardtab and scroll down to theExtrusion Control- Set Amount (mm) to

50. - Set Feedrate (mm/min) equivalent to

7 mm/s(which is420 mm/min). - Gently push the filament while simultaneously clicking the

Extrudebutton.

- Set Amount (mm) to

- Continue clicking

Extrudeuntil you see filament consistently extruding from the nozzle. Ensure the extruder gears are gripping and pulling the filament smoothly.

¶ 3. Execute the Cold Pull Macro

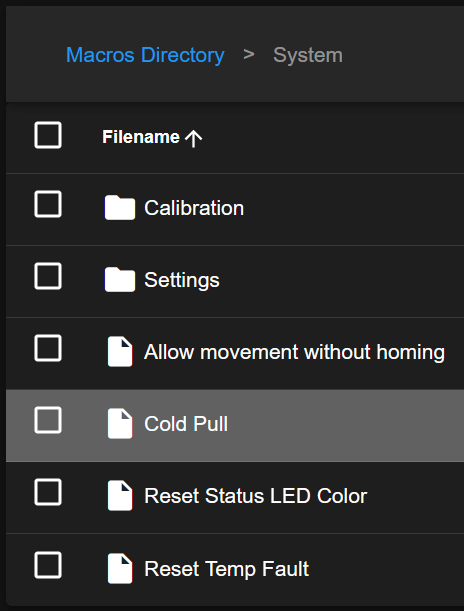

- Navigate: On the printer's web interface, go to the

Macrostab. - Select Folder: Tap on the

Systemfolder. - Run Macro: Tap the

Cold Pulloption.

-

Configure via Pop-up: A configuration window will appear on the screen. You must manually set the parameters for the Cold Pull:

-

Select Toolhead: Choose either T0 or T1, corresponding to the toolhead you loaded the filament into in Step 2.

-

Enter Temperature: Input the desired initial heating temperature for the selected toolhead.

- Guidance: Enter the typical printing temperature for the filament you loaded, or slightly higher (e.g.,

+10°Cto+20°C). This ensures the filament fully melts initially.- Example for PLA:

210-230°C - Example for PETG:

240-260°C - Example for Nylon (for cleaning):

250-270°C - Example for higher temp materials (ABS, PC, etc.): Use their respective print temps or slightly above.

- Example for PLA:

- Guidance: Enter the typical printing temperature for the filament you loaded, or slightly higher (e.g.,

-

-

Automatic Process Begins: The printer will now automatically:

- Heat the selected toolhead to the temperature you specified.

- Hold that temperature briefly to ensure the filament is fully molten.

- Begin a controlled cooling sequence to bring the filament down to the optimal semi-solid state for removal.

¶ 4. Perform the Pull

- Wait for Prompt/Temperature: The printer's interface should indicate when it's ready for the filament to be pulled as it reaches the correct temperature during the controlled cooling phase. The optimal pull temperature varies by material but is often in the

100°Cto160°Crange (Nylon might be slightly higher). Follow the printer's prompt. - Grip Filament: Once the printer indicates it's ready, firmly grip the filament just above the extruder assembly.

- Pull Firmly: Pull the filament directly upwards out of the extruder and hotend path in one smooth, continuous, and firm motion. Do not yank violently, but apply consistent force.

¶ 5. Inspect the Result

- Examine Tip: Look closely at the end of the filament you just removed. A successful Cold Pull will typically have a tip shaped like the inside of the nozzle cavity.

- Check for Debris: Observe the color and texture of the tip. You may see dark specks, discolored streaks, or small chunks of debris embedded in the filament – this is the contamination that has been successfully removed from your hotend.

¶ 6. Repeat if Necessary

- If the filament broke off inside the hotend during the pull, or if the removed tip still looks very dirty (indicating significant residue remains), repeat the Cold Pull procedure starting from Step 2 (Reload Filament).

- Continue performing Cold Pulls until the filament tip comes out clean and fully formed, indicating the melt path is clear.

¶ Troubleshooting & FAQs

- Q: The filament breaks off inside when I try to pull it.

- A: This usually means you pulled too late (too cold), too early (too hot), or not with a smooth, steady force. Try running the macro again. Ensure you pull firmly and continuously as soon as the printer indicates or reaches the target temperature zone.

- Q: The Cold Pull macro won't start or gives an error.

- A: Ensure filament is actually loaded into the hotend. Verify the correct toolhead (T0/T1) is active or selected. Check the printer interface for any specific error messages.

- Q: The filament tip looks clean, but I still have extrusion problems.

- A: A Cold Pull mainly clears the nozzle and melt path. If issues persist, the problem might be a more severe clog higher up (heatbreak), an issue with the extruder gears, incorrect filament diameter, or software/slicer settings.

- Q: Can I use PLA/PETG for a cold pull?

- A: Yes, you can use most filaments. However,

Nylonis generally considered superior for cleaning purposes due to its properties. If just removing the current filament, using the same type often works fine.

- A: Yes, you can use most filaments. However,

- Q: What temperature should I enter in the Cold Pull pop-up?

- A: Use the normal printing temperature for the filament you are using for the pull, or about 10-20°C higher. Using too low a temperature might prevent the filament from melting properly initially; too high isn't usually necessary unless dealing with very high-temp materials. See the examples in Step 3.4.

¶ Conclusion & Additional Resources

The Cold Pull procedure is a valuable technique for maintaining a clean hotend, ensuring smooth filament flow, and preventing issues when changing materials. Using the built-in macro simplifies the process, allowing you to effectively remove contaminants and keep your Vision Miner 22IDEX printing reliably.