¶ Brief Overview

Filament sensor errors, typically manifesting as random or false triggers during printing, can cause frustrating print interruptions. This guide explains a known cause for such behavior on some Vision Miner 22IDEX printers—related to the sensor housing from a specific production batch—and provides solutions to rectify the issue, ensuring smooth and uninterrupted printing.

¶ Tools & Materials

- Recommended Filament

- Sensor Housing STL File (Link to be provided by Vision Miner, see section 2.1)

- PH2 Phillips Screwdriver

¶ Safety & Pre-checks

- If you choose to reprint the sensor housing, ensure the printer used for this task is well-calibrated to produce accurate parts.

- Before disassembling any part of the filament sensor, ensure the printer is powered off and cooled down, if recently used.

Warning: If you temporarily disable the filament sensor(s), the printer will not automatically pause if the filament genuinely runs out or breaks. You will need to monitor your filament levels manually to prevent print failures (e.g., printing in air).

¶ Step-by-Step Instructions

¶ 1. Understanding the Issue: Random Sensor Triggers

The primary symptom is your print pausing unexpectedly, with the printer reporting a filament runout even though filament is still loaded and feeding correctly. This issue was identified on a small batch of Vision Miner 22IDEX printers and is typically due to a slight dimensional inconsistency in the filament sensor's plastic housing, which can cause the internal sensor flag or mechanism to stick intermittently.

¶ 2. Solution Options

There are two permanent solutions to address the sticking sensor housing and one temporary workaround to prevent print interruptions.

¶ 2.1. Permanent Solution A: Reprinting the Sensor Housing

Vision Miner has an updated design for the sensor housing that resolves the potential sticking issue. If you have access to another 3D printer (or can use your Vision Miner 22IDEX once the sensor is temporarily disabled), you can print this improved part yourself.

- Download the STL File: Obtain the corrected sensor housing STL file.

- Select Material: Use a durable and high temperature material.

- Recommendation: Nylon are generally suitable for functional printer parts. However, please confirm the specific material recommendation with Vision Miner support to ensure optimal performance and compatibility.

- Slicing and Printing:

- Slice the STL file using your preferred slicer.

- Crucial Tip: When printing the housing, ensure you use ample part cooling fan, especially for any overhangs or intricate features. This is critical for the part to be dimensionally accurate and for the sensor mechanism to operate freely without sticking.

- Replace Housing: Once printed carefully replace the existing sensor housing(s) on your printer with the newly printed one(s).

If you prefer not to print the part yourself, or if you are unable to, Vision Miner will provide the corrected sensor housing(s) free of charge for printers affected by this specific batch issue.

- To request a replacement, please Contact Vision Miner Support.

- Include your printer's serial number and a brief description of the random filament sensor errors you are experiencing.

¶ 2.3. Temporary Workaround: Disabling the Filament Sensor(s) via Macros

To prevent false triggers from interrupting your prints while you await or prepare a permanent solution, you can temporarily disable the affected filament sensor(s).

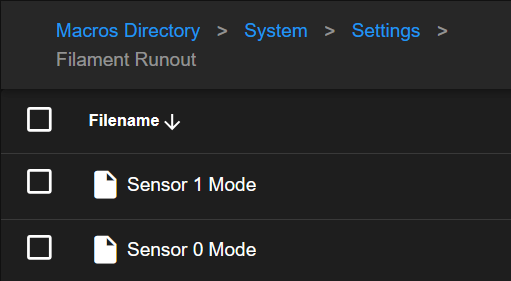

- On your printer's web interface, navigate to the Macros tab.

- Open the following folder path:

System > Settings > Filament Runout. - In this folder, you will find macros named

Sensor 0 Mode(for the T0/left extruder sensor) andSensor 1 Mode(for the T1/right extruder sensor).

- To disable a sensor (e.g., Sensor 0):

- Run the Sensor 0 Mode macro.

- You will be prompted with options. Select Disable.

- The sensor will now be disabled and will not trigger filament runout alerts.

- Repeat the process for Sensor 1 Mode if both sensors are exhibiting issues.

Important: This is a temporary workaround. Remember to re-enable your filament sensor(s) using the same macros (this time choosing an "Enable" option) once you have implemented a permanent fix (replacing the housing). This will restore the valuable filament runout detection feature.

¶ Troubleshooting & FAQs

-

Q: I reprinted the housing with the new file, but the sensor still sometimes triggers. What now?

A: First, double-check your reprinted part for any print defects, especially stringing or imperfections around small features or channels where the filament passes or the sensor mechanism moves. Ensure the filament path leading to and from the sensor is smooth and free of snags. If issues persist, there might be another cause; please Contact Vision Miner Support. -

Q: How do I know which sensor is 'Sensor 0' and which is 'Sensor 1'?

A: Typically, Sensor 0 corresponds to the left extruder (T0), and Sensor 1 corresponds to the right extruder (T1). If you are unsure, you can test by triggering one sensor (e.g., by removing filament from T0) and see which sensor status changes in the printer interface (if shown) or which one is reported if an error occurs (before disabling). -

Q: If I disable the sensors, will it affect my print quality?

A: Disabling the sensors themselves will not directly affect print quality. However, if you run out of filament without the sensor to pause the print, the extruder will continue to attempt printing without material, leading to an incomplete or failed print.

¶ Conclusion & Additional Resources

Random filament sensor triggers can be disruptive, but are often resolvable by addressing the sensor housing. Vision Miner is committed to ensuring your 22IDEX printer operates reliably. We recommend implementing one of the permanent solutions (reprinting or requesting a replacement housing) for long-term stability.

For direct assistance, STL files, material recommendations, or replacement parts: