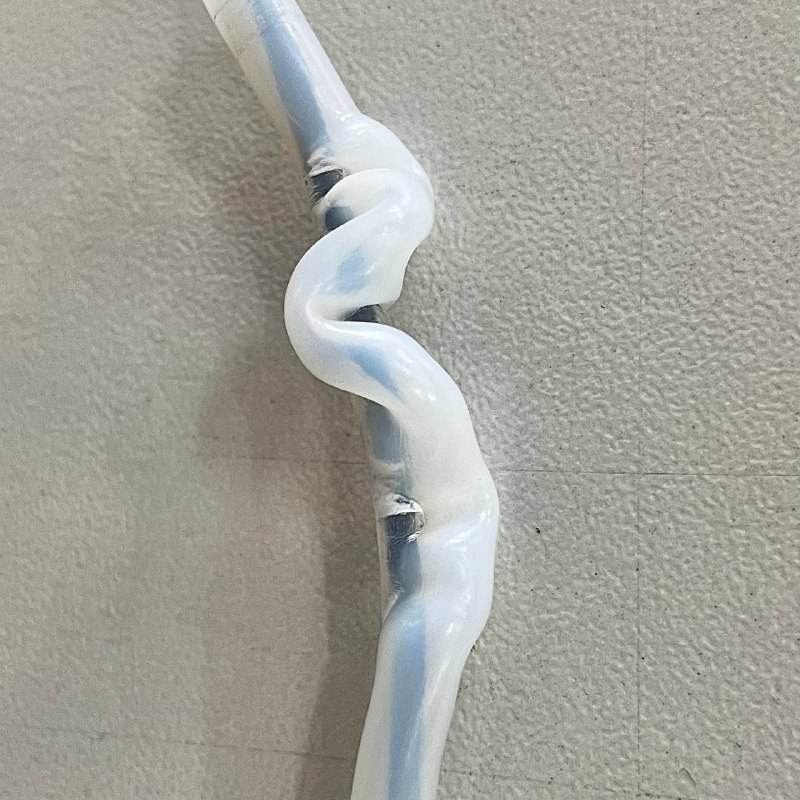

¶ Filament Tube Compressing (Accordion Effect)

¶ Brief Overview

This section addresses an issue where the filament guide tube (often a PTFE tube) between the filament sensor and the extruder head assembly compresses or "crumbles" like an accordion. This deformation is a critical indicator of a filament feeding problem.

¶ Tools & Materials

For diagnosing and resolving this issue, you may need the following:

- Visual Inspection Aid - For examining the filament path.

- Flush Cutters - For cleanly cutting filament if needed.

- Replacement PTFE Tube - If the current tube is damaged.

- Thicker-Walled PTFE Tube - Vision Miner can supply, optional upgrade upon request

¶ Safety & Pre-checks

Before proceeding, please observe the following safety precautions and preparatory checks:

Warning: Avoid forcibly pulling or pushing filament if it feels significantly stuck. This can damage the extruder mechanism or other components.

- Stop the Print: If the issue occurred during a print, cancel the print job from the printer's interface.

- Allow Cooling: If any parts like the nozzle were heated, allow them to cool to a safe temperature if you anticipate needing to work near them (though this procedure primarily focuses on the cold path).

- Observe the Filament Path: Make a mental note of the current filament path and how the tube is currently situated.

¶ Step-by-Step Instructions

¶ 1. Identifying the Issue

- Visually inspect the filament guide tube that runs from the filament sensor or the filament entry point towards the extruder.

- Look for signs of compression, buckling, or an "accordion-like" deformation in the tube. This indicates that the tube has been subjected to excessive axial force.

¶ 2. Understanding the Cause

The filament tube compresses because:

- The extruder motor is actively trying to push filament towards the hotend.

- The filament itself is encountering resistance and cannot move freely. Common points of resistance include tangled filament on the spool or obstructions in the path.

- Since the filament is relatively rigid and cannot compress, the force exerted by the extruder motor is transferred to the guide tube.

- The guide tube, typically made of PTFE, is relatively thin-walled and flexible, causing it to buckle or "crumble" under this compressive load.

¶ 3. Inspecting the Filament Path

Carefully examine the entire filament path for any signs of obstruction or restriction.

- Check the Filament Spool:

- Inspect the filament spool for any tangles or crossovers. Filament can sometimes get wound incorrectly, causing it to snag and prevent smooth unwinding.

- Ensure the spool can rotate freely on its holder.

- Examine Filament Entry Points:

- Check where the filament enters the filament sensor and where it enters the extruder assembly.

- Ensure there are no sharp bends, kinks, or debris obstructing the filament's entry.

- Inspect the Tube Internally (If Possible):

- If the tube is easily detachable and the filament is removed, check if there's any internal debris or kinking within the tube itself, though external compression is the primary focus here.

¶ 4. Resolving Filament Obstructions

Once the cause of the filament restriction is identified, take the appropriate steps:

- Untangle Filament: If the filament is tangled on the spool, carefully unwind the tangled portion and ensure the filament feeds smoothly off the spool. You may need to manually feed some length to confirm.

- Clear Obstructions: If an obstruction is found elsewhere (e.g., a piece of debris, a poorly routed tube creating a sharp bend), remove the obstruction or reroute the tube for a smoother path.

- Re-feed Filament: After resolving the obstruction, carefully re-feed the filament towards the extruder.

Tip: When loading new spools, always secure the loose end of the filament to prevent it from tangling.

¶ 5. Assessing Tube Damage & Replacement

After addressing the filament obstruction, assess the condition of the filament guide tube.

- If the tube is only slightly compressed but springs back to its original shape and allows smooth filament passage, it may still be usable. However, monitor it closely.

- If the tube is severely kinked, creased, or permanently deformed, it can create ongoing friction and feeding issues. In such cases, the tube should be replaced.

- To obtain a replacement PTFE tube specifically for your Vision Miner 22IDEX, please contact our support team.

¶ 6. Considering a Thicker Tube (Optional Upgrade)

If you find that the filament tube compression issue occurs frequently, even after ensuring a clear filament path, you might consider upgrading to a thicker-walled PTFE tube.

- A thicker-walled tube offers greater resistance to compression and can be more durable in demanding situations or with particularly rigid filaments.

- Contact Vision Miner support to discuss the availability and suitability of a thicker-walled tube for your printer model.

¶ Troubleshooting & FAQs

-

Q: The filament tube compressed, but I don't see any tangles on the spool. What else could it be?

A: Check for other sources of friction or obstruction:- Is the filament diameter consistent, or is there a thick spot?

- Is the filament path making any excessively sharp turns?

- Is the filament sensor introducing unexpected friction?

- Is there any debris inside the extruder inlet?

- Is the extruder itself jammed (though this procedure focuses on pre-extruder issues)?

-

Q: Can I straighten a compressed PTFE tube?

A: While you might be able to somewhat reshape a mildly compressed tube, any kinks or creases often remain points of weakness or friction. Replacement is generally recommended for reliable performance if the deformation is significant. -

Q: Will a compressed tube cause under-extrusion?

A: Yes, a compressed or kinked tube can increase friction on the filament, making it harder for the extruder to push it consistently. This can lead to under-extrusion and poor print quality. -

Q: How do I order a new filament tube?

A: Please contact Vision Miner support with your printer details, and they will assist you in ordering the correct replacement part.

¶ Conclusion & Additional Resources

Successfully diagnosing and resolving filament tube compression is key to maintaining the reliability of your Vision Miner 22IDEX. Always ensure your filament is loaded correctly and the feed path is unobstructed. After implementing these checks and solutions, your printer should resume normal operation.

For persistent issues or if you require a replacement tube:

Consider performing a small test print after resolving the issue to confirm that filament is feeding smoothly and the tube remains in good condition.