¶ Brief Overview

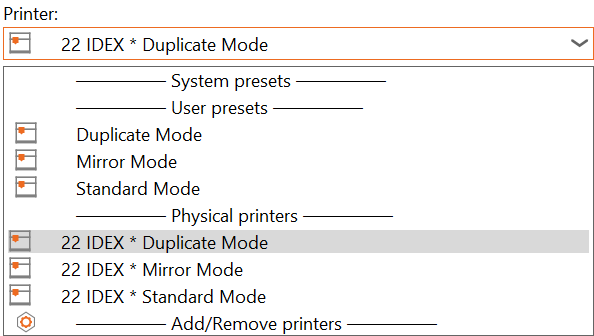

Mirror and Duplicate modes on the Vision Miner 22IDEX utilize both extruders simultaneously to produce two objects at once, significantly boosting productivity. Mirror Mode prints a symmetrical (mirrored) version of a part, while Duplicate Mode produces two identical copies. Achieving success with these advanced modes requires specific considerations for part placement, bed adhesion strategies, and calibration.

¶ Tools & Materials

- Vision Miner 22IDEX 3D Printer

- Filament (ensure enough for two parts)

- Slicing software compatible with Vision Miner 22IDEX IDEX capabilities

¶ Safety & Pre-checks

- General Calibration: Ensure your printer has undergone standard calibrations (e.g., Z-offset) before attempting Mirror or Duplicate prints.

- Extruder Check: Verify that both extruders (T0 and T1) are clean, loaded with filament, and extruding correctly in single-extruder mode first.

- Clear Print Bed: Ensure the print bed is clean and clear of any previous prints or debris.

Warning: Mirror and Duplicate modes have distinct operational mechanics and setup requirements. Failure to configure them correctly can lead to print failures or collisions. Pay close attention to the specific instructions for each mode.

¶ Step-by-Step Instructions

¶ General Recommendations for Mirror & Duplicate Modes

These recommendations apply to both Mirror and Duplicate printing modes and are crucial for successful prints.

¶ 1. Using a Raft

For both Mirror and Duplicate modes, it is strongly recommended to use a raft.

- Purpose: A raft provides a stable, uniform foundation for your prints, which is especially beneficial in these modes. It helps compensate for any minor variations in bed leveling across the larger area utilized by both print heads and significantly improves first-layer adhesion.

- Recommendation: We advise always using a raft as a default best practice for these modes to ensure reliability.

Note: An exception can be made if you are printing relatively small parts and you are an experienced user prepared to meticulously monitor the first layer and perform precise First Layer Flow Calibration (see below). If you choose not to use a raft under these specific conditions, it is at your own risk. For most users and most prints, a raft is the preferred method.

¶ 2. First Layer Flow Calibration

Calibrating your first layer flow is critical, especially when not using a raft, and particularly vital in Duplicate Mode where automatic bed leveling compensation is disabled.

- Purpose: Proper first layer flow ensures correct extrusion volume for the initial layer, leading to good adhesion and a solid foundation for the rest of the print.

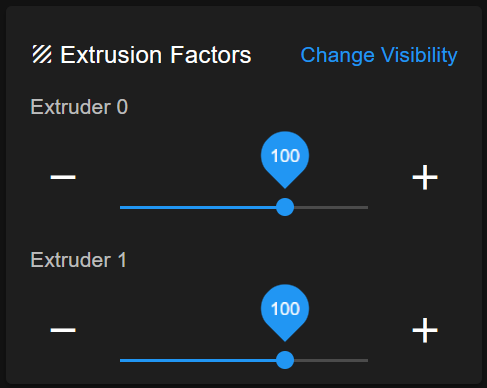

- Procedure: This typically involves printing a single-layer test pattern and adjusting the slicer's "Initial Layer Flow" (or equivalent) setting until the lines are perfectly squished, with no gaps between them and no excessive material buildup. You can also control the first layer extrusion in the printer interface, under the

Statustab, in theExtrusion Factorswindow. Any extrusion adjustment made here only affect the current layer and will rest to default on the next one.

- Importance: Refer to the main Vision Miner documentation for detailed instructions on performing First Layer Flow Calibration. This step should not be skipped if you are aiming for high-quality, reliable IDEX prints.

¶ Configuring Mirror Mode

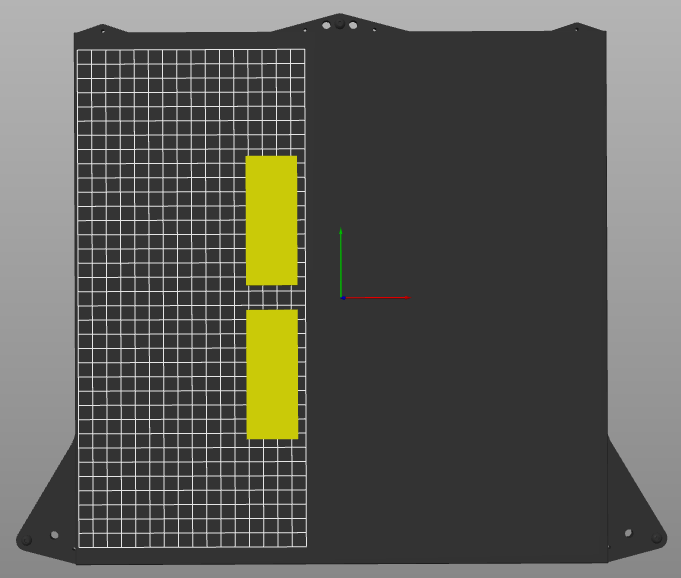

In Mirror Mode, the printer creates two parts that are symmetrical reflections of each other across the Y-axis centerline of the build plate.

¶ 1. Understanding Mirror Mode Mechanics

The two print heads move in a mirrored fashion. Imagine a line down the center of the Y-axis of your build plate; one head will print on one side, and the other will print the mirrored geometry on the other side.

¶ 2. Part Placement in Slicer for Mirror Mode

Optimal part placement is crucial for accuracy in Mirror Mode.

- Position Close to Center: Place your part (which will be mirrored) as close as possible to the centerline of the entire build plate. The original part should typically be placed on one side of this centerline (e.g., the right side, for T0, if T1 mirrors on the left).

- Orient Along Y-Axis: If your part has a longer dimension, orient it primarily along the Y-axis.

- Rationale: The closer the two (mirrored) printing paths are to each other (i.e., near the center of the bed), the less potential for any minute kinematic errors to be amplified. Placing parts further out towards the edges of the X-axis can increase the chance of slight misalignments.

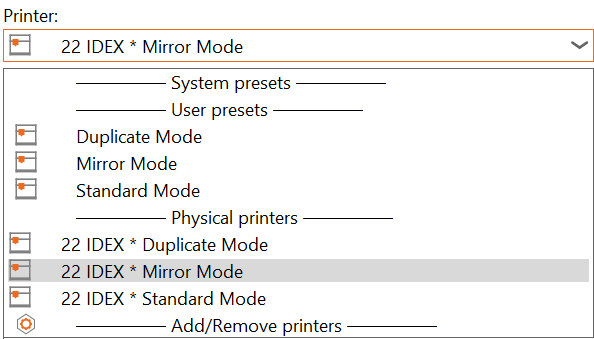

¶ 3. Slicer Settings for Mirror Mode

- In your slicing software, select the Mirror Mode option.

- Ensure your slicer is configured for the Vision Miner 22IDEX and its IDEX capabilities.

- Bed Leveling: In Mirror Mode, the printer's automatic bed leveling system (height map calibration) is typically active and helps ensure a good first layer for both mirrored parts.

¶ Configuring Duplicate Mode

In Duplicate Mode, the printer creates two identical copies of a part simultaneously. This is often the most challenging IDEX mode to perfect.

¶ 1. Understanding Duplicate Mode Mechanics

Both print heads move in tandem, maintaining a fixed X-axis offset from each other, to print two identical objects.

Important: Duplicate Mode is generally considered the most challenging IDEX mode because automatic bed height map calibration is disabled. This makes manual calibration and first layer settings paramount.

¶ 2. Part Placement in Slicer for Duplicate Mode

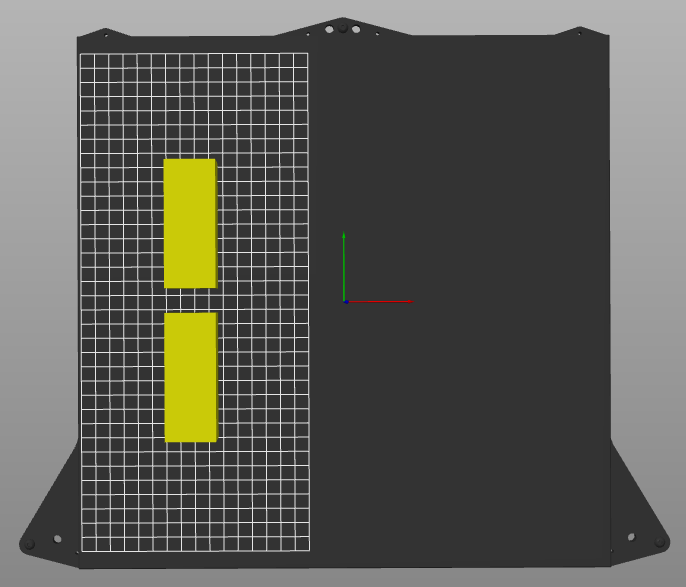

Careful placement is key to success in Duplicate Mode.

- Position in Respective Centers: Place the part you wish to duplicate in the center of the designated print area for one of the extruders (e.g., the left half of the bed for T0). The slicer will typically automatically position the duplicated part in the corresponding location for the second extruder (T1).

- Orient Along Y-Axis: Align the longest dimension of your part(s) along the Y-axis.

- Minimize X-Axis Footprint: It is critical to minimize the overall width (X-dimension) of the parts. For example, if printing two long, thin parts, orient them so their length runs along the Y-axis and their narrow width runs along the X-axis.

- Rationale: The distance between the two nozzles in Duplicate Mode is mechanically fixed. Automatic bed leveling compensation (height map) is turned off in this mode as it could interfere with the synchronized movement and cause collisions or leveling conflicts. Minimizing X-axis travel reduces the impact of any uncompensated minor bed tilt along the X-axis.

¶ 3. Slicer Settings for Duplicate Mode

- In your slicing software, select the Duplicate Mode option.

- Verify all settings are appropriate for the Vision Miner 22IDEX.

- Critical Bed Leveling Note: Re-emphasize that automatic bed height map calibration is DISABLED in Duplicate Mode. Your first layer success relies entirely on:

- A physically well-leveled bed.

- Precise Z-offset calibration.

- Correct First Layer Flow Calibration.

- The use of a Raft (highly recommended).

¶ Troubleshooting & FAQs

-

Q: My prints are misaligned or not symmetrical in Mirror Mode.

A: Check that the part was placed as close to the Y-axis centerline of the entire build plate as possible in the slicer. Further, verify your printer's core calibrations. Significant deviations might indicate a need for mechanical or firmware calibration review by support. -

Q: My first layer isn't sticking or is very uneven in Duplicate Mode.

A: This is common if precautions are missed.- Are you using a raft? This is highly recommended.

- Did you perform a meticulous First Layer Flow Calibration?

- Is your physical bed leveling and Z-offset as accurate as possible? Since auto-leveling is off, these manual steps are critical.

-

Q: Why is automatic bed leveling (height map) disabled in Duplicate Mode?

A: In Duplicate Mode, both nozzles must maintain a perfectly synchronized height relative to each other and their respective print areas. Applying independent Z-adjustments from a height map to each nozzle simultaneously could lead to conflicts, potential collisions, or uneven printing as they traverse the bed with a fixed mechanical offset. -

Q: Can I print two different parts in Duplicate Mode?

A: No. Duplicate Mode is designed to print two identical copies of the same part. For printing two different parts, you would use the printer in its standard sequential or multi-material modes (if applicable to the design). -

Q: Why should parts be oriented along the Y-axis, especially in Duplicate Mode?

A: Orienting parts along the Y-axis helps minimize their footprint along the X-axis. In Duplicate Mode, because bed leveling compensation is off, any slight tilt of the bed along the X-axis will have a more pronounced effect over a wider X-span. Keeping the X-dimension of the parts small reduces the impact of such an uncompensated tilt.

¶ Conclusion & Additional Resources

Mirror and Duplicate modes are powerful features of the Vision Miner 22IDEX that can significantly enhance your productivity. However, they demand careful attention to setup, part placement, and calibration, especially regarding the first layer. Always perform small test prints when trying a new material or complex geometry in these modes.

For further assistance or if you encounter persistent issues:

- Refer to your detailed Vision Miner User Manual for general calibration procedures.

- First Layer Flow Calibration Guide

- Contact Vision Miner Support