¶ Brief Overview

This guide explains how to replace the filament guide PTFE tube for either toolhead (T0 or T1) on the Vision Miner 22IDEX. The PTFE tube provides a low-friction path for the filament between the filament sensor at the rear of the printer and the extruder assembly on the toolhead. Replacing a worn or damaged tube can resolve filament loading issues and ensure smooth filament feeding.

¶ Introduction

The filament PTFE tube plays a crucial role in guiding the filament accurately and with minimal friction from the entry point (Filament Sensor) to the extruder gears. Over time, the inside surface of the tube can wear down, or the tube itself can become kinked or damaged. Symptoms of a problematic PTFE tube include difficulty loading or unloading filament, filament grinding in the extruder, or inconsistent extrusion. This procedure outlines how to safely remove the old tube and install a new one.

¶ Tools & Materials

- Replacement PTFE Tube (Must be the correct inner/outer diameter and length. Compare with the original tube.)

- Measuring Tool (Ruler or tape measure - recommended for verifying length)

- Utility Knife (Optional - potentially needed for trimming tube)

- Pliers (Optional - may assist in gripping the tube if difficult to pull)

¶ Safety & Pre-checks

Caution: While this procedure doesn't typically involve high voltages or extreme heat (unless filament was recently loaded), it's good practice to power off the printer and unplug the power cord for safety.

- Power off the printer and unplug the power cord (Recommended).

- Ensure you have the correct type and length of replacement PTFE tube.

- Clearly identify which toolhead's tube (T0/Left or T1/Right) you intend to replace. Note the corresponding Filament Sensor module at the rear of the printer on the same side.

- Gather necessary tools.

¶ Step-by-Step Instructions

¶ 1. Preparation

- Power Down: Turn off the printer using the main switch and unplug the power cord from the outlet (Recommended).

- Identify Target: Confirm which toolhead's tube (T0 or T1) needs replacing. Locate the corresponding Filament Sensor module at the printer's rear on the same side.

- Gather Supplies: Have the new PTFE tube ready.

¶ 2. Removing the Old PTFE Tube

¶ 2.1 Disconnect from Extruder

- Go to the target toolhead (T0 or T1).

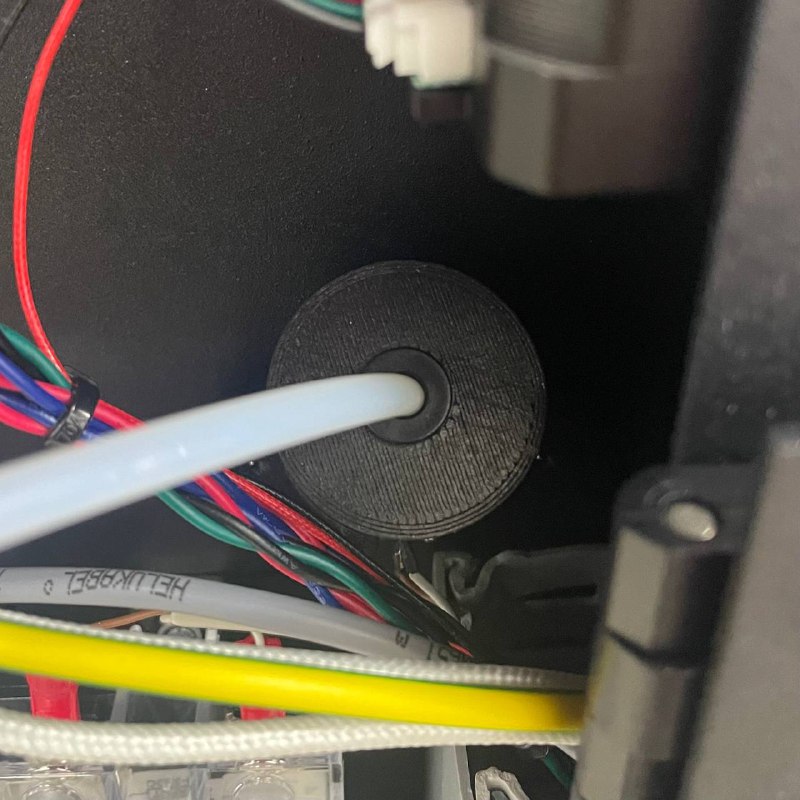

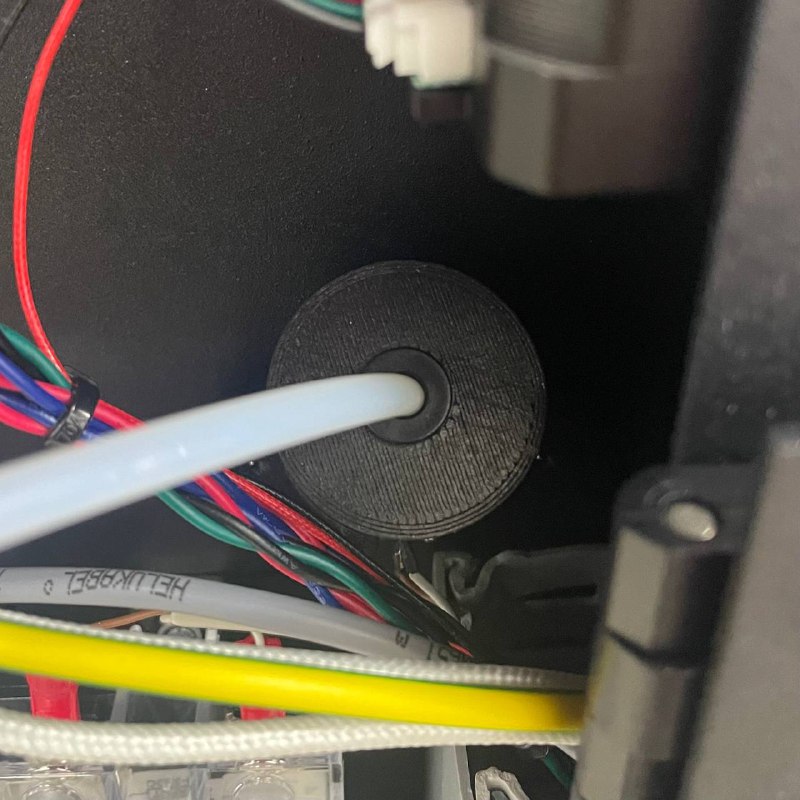

- Locate the Extruder assembly on the toolhead. Identify the PTFE Clip on the top where the filament guide tube enters.

- Press and hold down the top plastic ring of the PTFE Clip firmly towards the extruder body.

- While keeping the clip pressed down, grip the PTFE tube near the clip and pull it straight upwards and out of the PTFE Clip and extruder.

¶ 2.2 Disconnect from Filament Sensor

- Move to the rear of the printer. Locate the Filament Sensor module corresponding to the toolhead you are working on.

- Identify the PTFE Clip where the PTFE tube enters this module.

- Press and hold down the top plastic ring of this PTFE Clip firmly towards the sensor body.

- While keeping the collar pressed down, grip the PTFE tube near the clip and pull it straight outwards (away from the sensor) out of the PTFE Clip.

¶ 2.3 Remove Tube from Printer

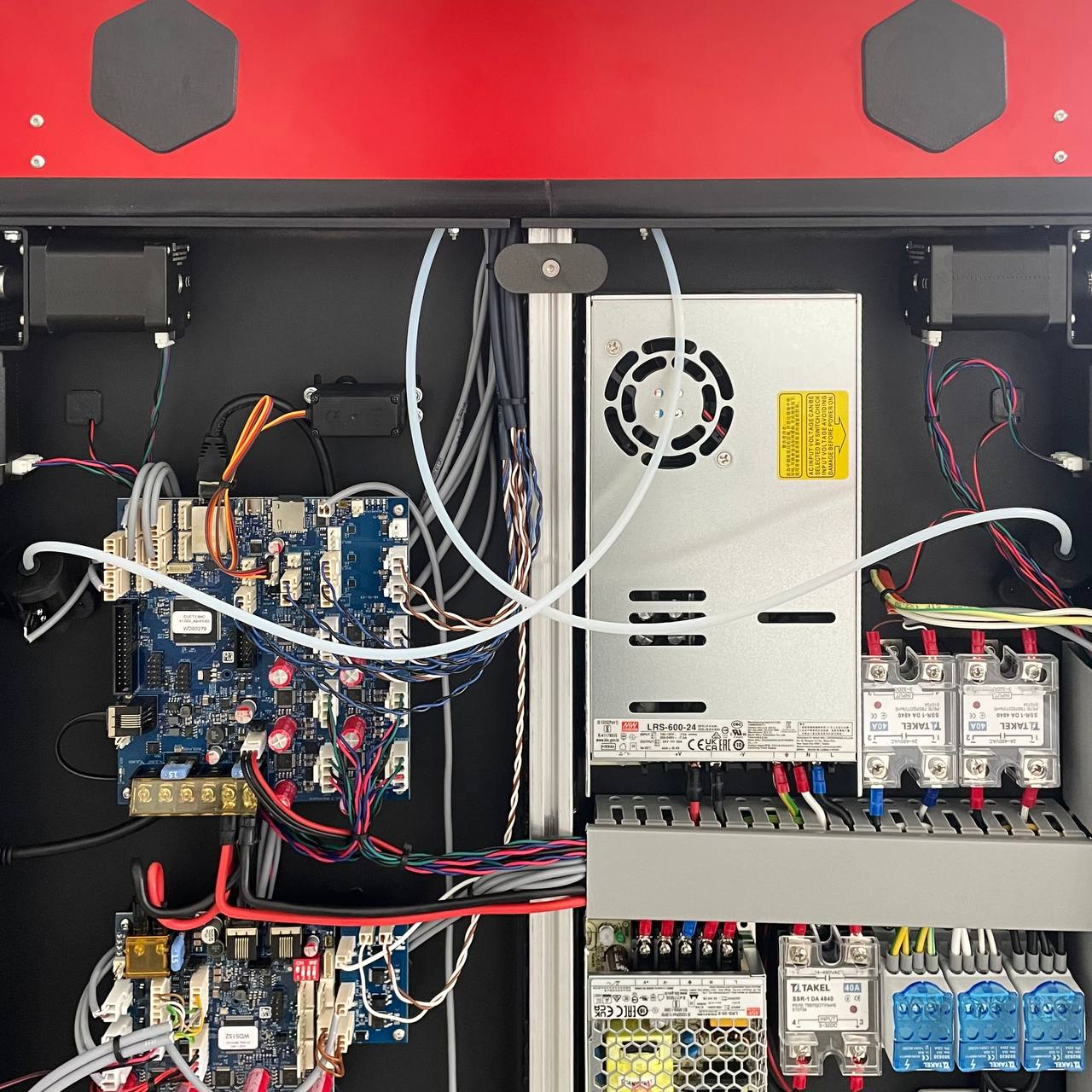

- Gently pull the now-disconnected PTFE tube free from the printer. Note its path through any cable channels or chassis openings. It typically runs alongside the toolhead's main wiring harness.

- (Recommended) Lay the old tube straight and measure its exact length using a ruler or tape measure. Keep this measurement for the new tube.

¶ 3. Installing the New PTFE Tube

¶ 3.1 Verify Tube Length

- Take your new PTFE tube. Compare its length to the old tube you just removed (or the measurement you took).

- If the new tube is longer, carefully cut it to the exact same length as the original using Utility Knife or a specialized PTFE tube cutter. Ensure the cut is clean and perpendicular (square) to the tube. A clean cut is vital for proper function.

Note: Using a tube that is too short or too long can cause filament path issues or strain.

¶ 3.2 Connect to Filament Sensor

- Take one end of the correctly sized new PTFE tube.

- Insert this end firmly and straight into the PTFE Clip on the corresponding Filament Sensor module at the rear of the printer.

- Push the tube in until it hits the internal stop and feels securely seated. Give the tube a gentle tug outwards to confirm it is locked in place by the clip.

¶ 3.3 Route the Tube

- Carefully feed the other end of the PTFE tube along the same path the old tube followed. Route it through any designated openings in the printer frame towards the target toolhead.

- Guide the tube above the flexible cable channel through the zip ties leading to the toolhead.

¶ 3.4 Connect to Extruder

- Bring the free end of the routed PTFE tube to the top of the target Extruder.

- Align the tube end with the PTFE Clip on the extruder.

- Insert the tube end firmly straight down into the PTFE Clip until it hits the internal stop and feels securely seated.

- Give the tube a gentle tug upwards to confirm it is locked in place by the clip.

¶ 4. Final Checks

- Double-check that both ends of the new PTFE tube are fully inserted and securely locked into their respective PTFE Clips (on the Filament Sensor and the Extruder).

- Inspect the routing path. Ensure the tube is not kinked, sharply bent, or pinched at any point. It should follow a smooth curve along the cable channel.

- Gently move the toolhead by hand (if printer is off) across its X-axis range to ensure the tube and cable bundle move freely without snagging or excessive tension.

- If you powered off the printer, reconnect the power cord and turn it on.

- Test the filament path by loading filament into the toolhead. It should load smoothly without unusual resistance or extruder clicking/grinding. Test unloading as well.

¶ Troubleshooting & FAQs

- Q: The PTFE tube is hard to remove from the PTFE Clip.

- A: Ensure you are pressing the release collar down fully and evenly while pulling the tube straight out. Wiggling the tube slightly while pulling might help, but primary force should be straight. Ensure no filament is inside the tube end causing a blockage.

- Q: The new tube won't insert fully or doesn't lock into the PTFE Clip.

- A: Check that the tube end is cut perfectly square and clean, with no burrs. Inspect the inside of the PTFE Clip for any debris or broken filament fragments. Ensure you are pushing the tube straight in with firm pressure until it bottoms out.

- Q: Filament jams, grinds, or is hard to load/unload after replacing the tube.

- A: Re-check the tube routing for any kinks or tight bends. Verify both ends are fully seated in the PTFE Clips. Ensure the tube is the correct length and inner diameter. A poorly cut tube end can also cause snags.

¶ Conclusion & Additional Resources

Replacing the filament PTFE tube is straightforward maintenance that can significantly improve filament feeding reliability. Ensuring the correct length, clean cuts, proper routing, and secure connections are key to a successful replacement.