¶ Brief Overview

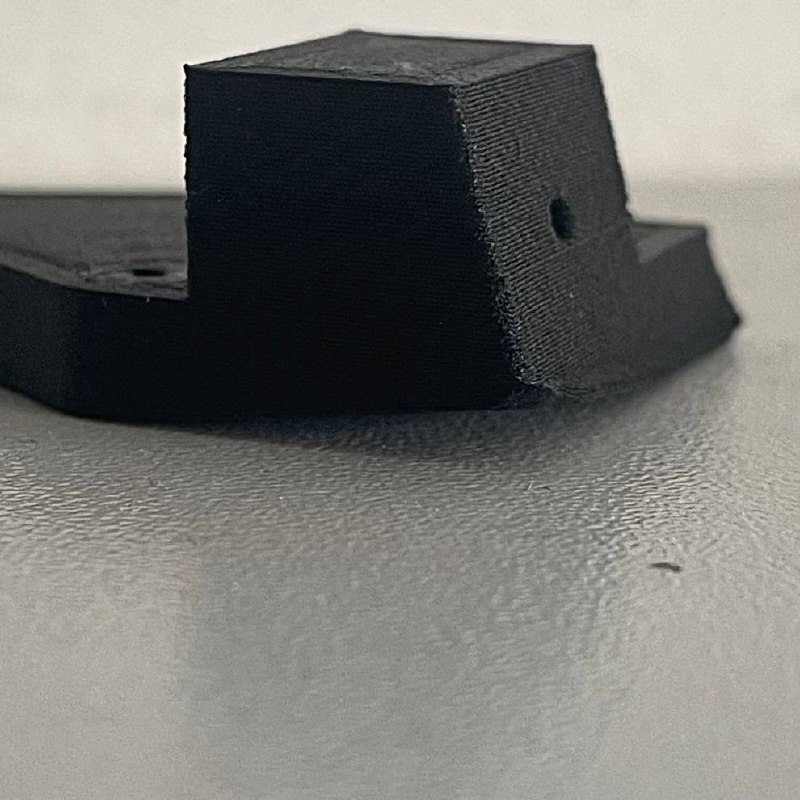

Warping occurs when the corners or edges of a 3D print lift and deform during the printing process. This phenomenon is caused by thermal contraction—the natural tendency of hot extruded materials to shrink as they cool, creating internal stresses that pull the print off the build plate. This guide provides a comprehensive workflow to diagnose and resolve warping issues on your Vision Miner 22IDEX.

¶ Tools & Materials

- Adhesion Promoter (Nano-polymer adhesive)

- Isopropyl Alcohol (90%+ concentration recommended)

- Lint-free Cloth

¶ Safety & Prechecks

Before starting, ensure your printer is in good working condition and has the latest firmware installed. Familiarize yourself with the basic operation of the printer, including heating and cooling procedures.

Warning: The print bed and hotend operate at high temperatures. Always exercise caution and use heat-resistant gloves when working near hot surfaces.

¶ Step-by-Step Instructions

This procedure is organized into four sections, from foundational checks to advanced fine-tuning. For best results, follow them in order, as a poorly calibrated machine will undermine any adjustments made later.

¶ 1. Printer Calibration: The Foundation

Proper calibration is the most critical factor in preventing warping. An improperly calibrated printer cannot produce a perfect first layer, which is essential for bed adhesion.

- Perform Mesh Bed Leveling: Proceed with a mesh bed leveling calibration. This advanced process maps microscopic variations across the build plate, ensuring the nozzle maintains a precise and consistent height everywhere.

Mesh Bed Leveling Guide - Tune the Live Z-Offset: As the first layer of a test print begins, perform a Live Z-Offset adjustment. This final micro-adjustment is crucial to achieving the perfect amount of "squish," ensuring the filament firmly bonds to the build surface.

¶ 2. Build Surface & Adhesion

A strong bond between the first layer and the build plate is necessary to resist the pulling forces of thermal contraction.

- Clean the Build Surface: Thoroughly clean the build plate with Isopropyl Alcohol and a lint-free cloth. This removes any oils, dust, or residue that can interfere with adhesion.

- Apply an Adhesion Promoter: For challenging materials, apply a thin, even layer of an adhesion promoter like a glue stick or a specialized nano-polymer adhesive. This significantly increases the bond between the print and the plate.

Tip: A little goes a long way. A single, smooth layer of adhesive is more effective than a thick, uneven application.

¶ 3. Temperature Management

Controlling the thermal environment is key to minimizing the temperature differences that cause warping.

- Set Optimal Bed Temperature: Ensure your bed temperature is set correctly for your material. A hot build plate keeps the base of the print in an expanded state, helping it stay adhered and resisting the pull from upper layers as they cool.

- Maintain Chamber Temperature: For high-temperature materials like ABS or PEEK, a heated chamber is critical. A stable, elevated ambient temperature reduces the thermal gradient between the extruded plastic and its surroundings, which drastically lowers the internal stresses that lead to warping.

¶ 4. Slicer Settings: Fine-Tuning the Print

Slicer settings can be adjusted to either increase first-layer adhesion or reduce the overall stress within the part.

¶ Improving First-Layer Adhesion

- Add a Brim: In your slicer software, add a brim to your model. A brim increases the first layer's total surface area, providing extra grip on the build plate.

- Increase First Layer Width: Set the first layer extrusion width to a higher value, such as

150%. This creates wider lines with more surface area, enhancing their ability to stick. - Decrease First Layer Speed: Print the first layer at a significantly slower speed (e.g.,

20 mm/s). This gives the molten plastic more time to properly bond with the build surface.

¶ Reducing Internal Stress

The core principle here is that less material results in less mass that cools and contracts.

- Reduce Infill Density: Lowering the infill percentage reduces the amount of material inside the part, which in turn lessens the cumulative force pulling the print inwards as it cools.

- Reduce Perimeters and Solid Layers: The densest areas of a print, like solid top/bottom layers and perimeters, generate the most stress. Decreasing the number of perimeters and solid bottom layers can significantly mitigate warping on large, solid models.

- Use a High-Temperature Profile: Select a profile designed for high-temperature materials. These profiles often use specialized infill patterns, such as Gyroid, which are engineered to distribute internal stress more effectively than standard linear infills, thereby reducing warping.

¶ Troubleshooting & FAQs

-

Why do my prints only warp on large models?

The more material a print has, the stronger the cumulative force of thermal contraction becomes. Large, solid parts are more susceptible because they have greater internal stress. Focus on temperature management and reducing infill density. -

I've done everything here and still see minor lifting. What else can I do?

Ensure your Live Z-Offset is perfectly tuned, as this is often the final piece of the puzzle. Also, consider adding a larger brim or even a raft in your slicer settings for maximum adhesion. -

Why is a heated chamber so important for some materials?

A heated chamber minimizes the temperature difference between the extruded plastic and the ambient air. This drastically reduces how quickly the upper layers cool and contract, thereby lowering the internal stress that causes warping.

¶ Conclusion & Additional Resources

By systematically addressing calibration, adhesion, temperature, and slicer settings, you can effectively eliminate warping and produce reliable, high-quality parts. For recurring issues, we recommend running a full calibration test print after making adjustments.

For more detailed information on specific procedures, please consult the following resources: