¶ Introduction

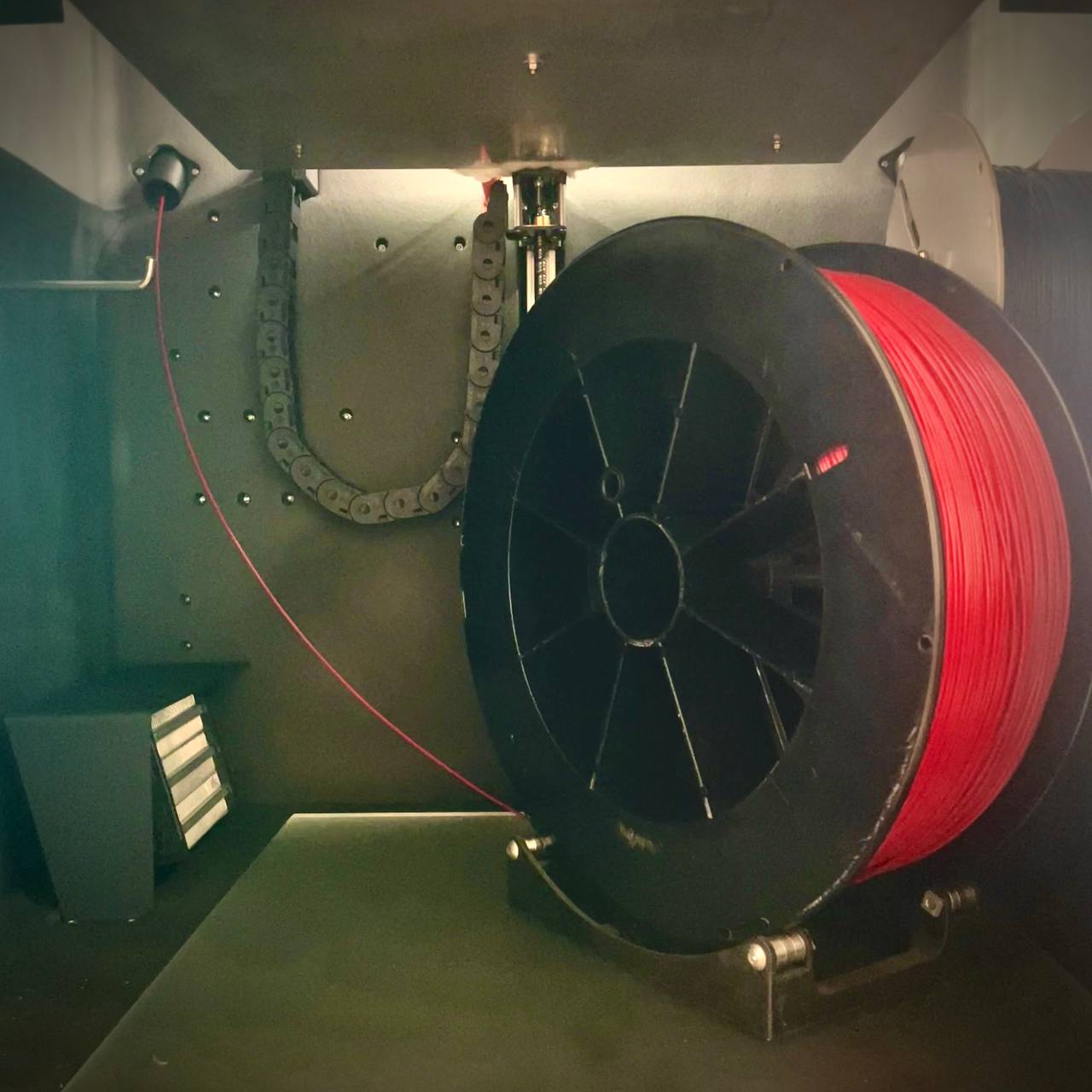

The 22IDEX is designed to be a turnkey solution with built-in filament drying capabilities. This allows you to dry and maintain your filament while printing. The machine includes two dedicated spool holders inside the chamber, designed to fit most standard 1kg spools.

However, if you wish to use larger spools—such as 2kg or bigger—you have two primary solutions:

- Placing the spool inside the heated chamber (if you have enough space).

- Rerouting the filament tubes outside the chamber to feed from an external spool.

Below, we describe both approaches in detail. The second solution also includes step-by-step instructions on bypassing (or removing) the filament sensor if needed and installing a printed adapter with T-nuts and screws.

¶ Solution 1: Placing the Spool Inside the Heated Chamber

If you are printing shorter parts and have space on the chamber floor, you can place a larger spool inside the heated chamber:

- Place the Spool on the Bottom

- Use a spool holder with bearings placed on the bottom of the chamber.

- 3D-printable spool holders with bearings are widely available online. We will soon provide our own design as well.

This method keeps your larger spool inside the chamber, allowing you to maintain a heated, low-humidity environment around the filament.

¶ Solution 2: Rerouting the Filament Tubes Outside the Chamber

If you are printing tall parts or otherwise need the interior space, you may want to place the large spool outside the 22IDEX and reroute your filament feed tubes. Follow these steps:

¶ 1. Decide Whether to Bypass or Remove the Filament Sensor

By default, the 22IDEX uses a filament sensor inside the chamber (for v2) or on the back panel near the main board (for v3). When moving the filament feed outside the machine, you can:

- Bypass the sensor (recommended): This involves unplugging the existing PTFE tube from the sensor and routing it directly to your extruder.

¶ 2. Remove or Disconnect the Filament Tube

-

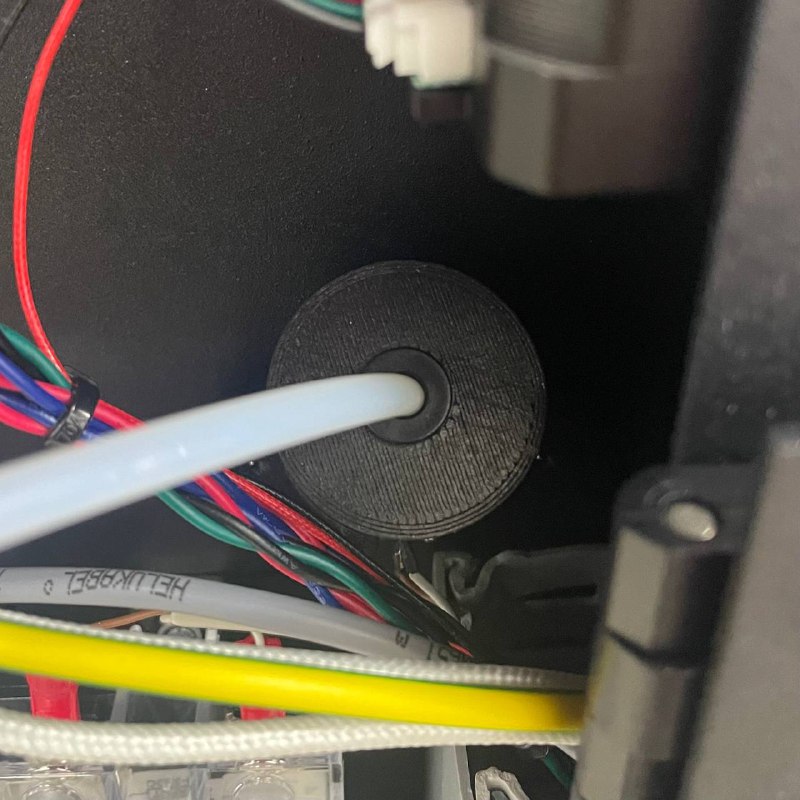

Locate the PTFE Fitting

- For v2 machines, the fitting is inside the chamber.

- For v3 machines, the fitting is outside on the back panel near the main board.

-

Detach the PTFE Tube

- Push down on the PTFE fitting and carefully pull the filament tube out.

- If bypassing the sensor, remove the tube from the sensor’s fitting.

- Push down on the PTFE fitting and carefully pull the filament tube out.

-

Pull the Tube From the Machine (If Reusing the Same Tube)

- Carefully thread the tube out of the chamber.

- Do not apply excessive force to avoid damaging components.

¶ 3. Reroute the Filament Through the Back of the Machine

-

Route Over the Top Cable Chain

- Beginning at the extruder, run your filament tube the same way it normally goes over the top cable chain.

-

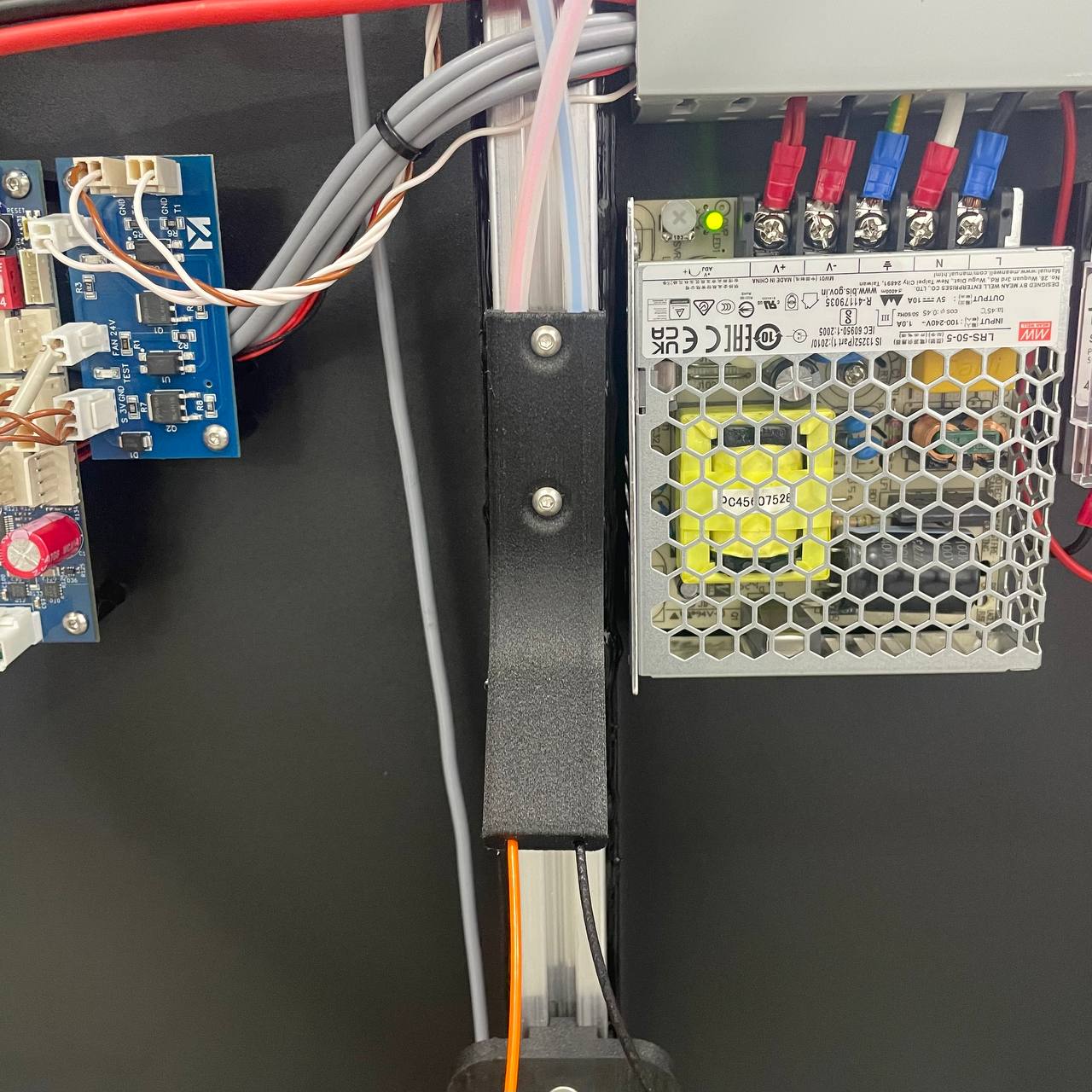

Use the Rectangular Cutout

- At the rear of the machine, locate the rectangular cutout or opening where the cable chains enter the frame.

- Feed the PTFE tube through this opening alongside the existing wiring harness.

- This will guide the tube into the machine’s electronics bay or out the back panel, depending on your model.

-

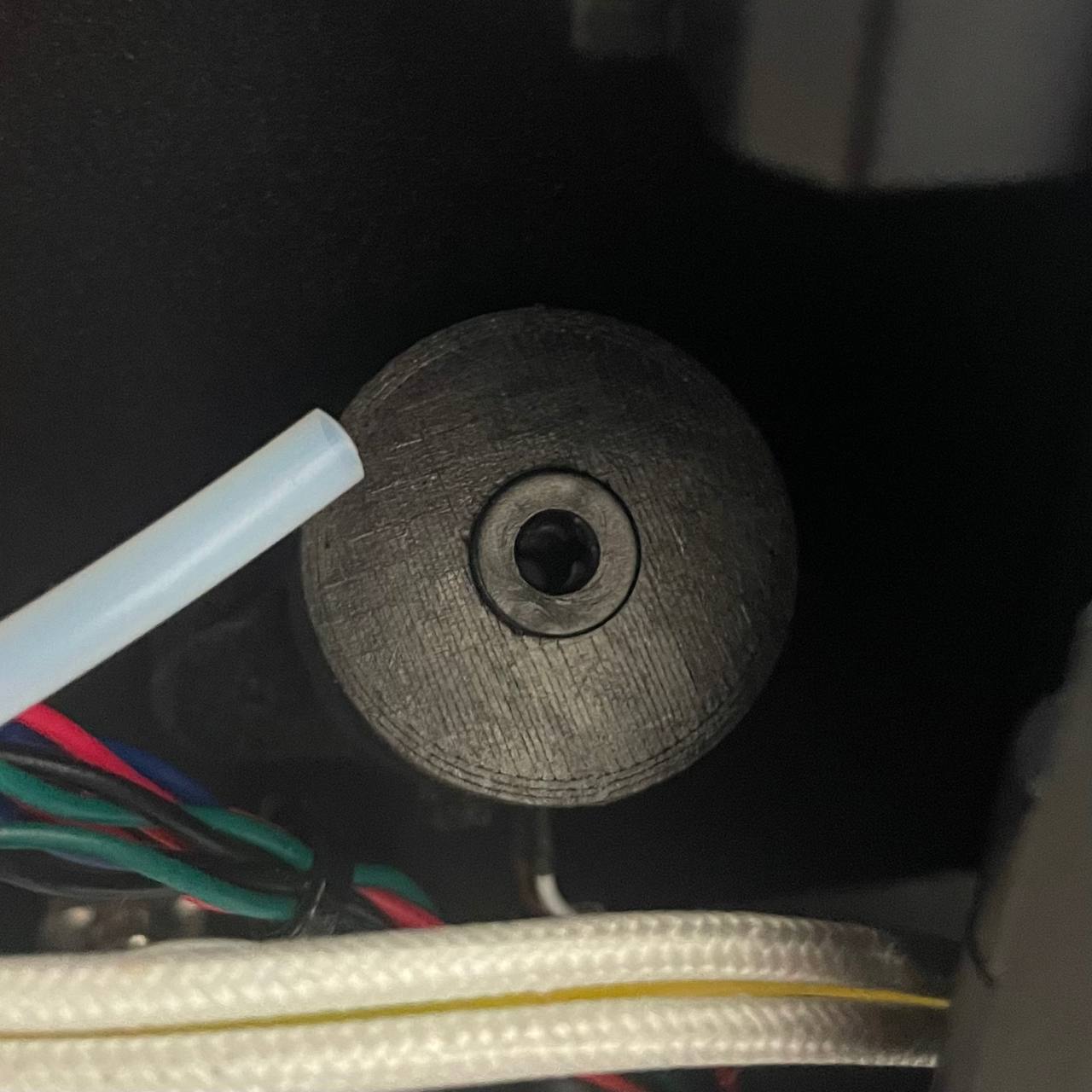

Print and Install the PTFE Tube Adapter

- Download and 3D print the PTFE Tube Adapter.

- Attach this adapter to the machine’s aluminum extrusion using two M3 x 14mm screws and two M3 T-nuts.

- This adapter helps secure the tube and keep it from kinking or bending sharply.

¶ 4. Set Up the External Spool

-

Place the Spool Externally

- Position your large spool on an external stand or spool holder outside the machine.

- Ensure the spool can unwind freely without tangling.

-

Feed Filament Through the PTFE Tube

- Insert the filament into the external end of your PTFE tube.

- Manually push it until it reaches the extruder.

-

Secure and Protect the Spool

- Because the spool is now in open air, it can absorb moisture.

- Consider storing it in a dry box or using a filament oven or large storage container with desiccant to keep humidity low.

¶ Conclusion

By following these steps, you can efficiently use both standard and larger spools with your 22IDEX printer. The built-in drying capabilities and versatile spool holder design ensure that your filament remains dry and ready for high-quality prints—even if you opt to bypass the internal filament sensor to accommodate very large external spools.

If you have any further questions or need assistance, please contact our support team. We are here to help you get the best possible experience from your 22IDEX printer!