¶ Brief Overview

This guide details the correct procedure for tightening the nozzle on the Vision Miner 22IDEX hotend. Proper tightening ensures a leak-proof seal between the nozzle and the heatbreak, which is essential for reliable printing and preventing filament leaks. This procedure MUST be performed while the hotend is heated and ONLY after all filament has been completely removed via a Cold Pull.

¶ Introduction

Ensuring your nozzle is correctly tightened against the heatbreak is a critical maintenance step. An improperly tightened nozzle can lead to filament leaking from the threads above the nozzle, causing print failures and potentially damaging hotend components. Tightening must be done while the hotend is hot because thermal expansion affects the components; tightening cold will likely result in leaks once the hotend reaches operating temperature. Critically, all filament must be removed before heating and tightening to prevent it from expanding or burning inside the hotend, which can cause severe clogs.

Purpose: To create a secure, leak-proof seal between the nozzle and heatbreak.

Scope: Covers filament removal prerequisite, heating methods, and the physical tightening process with recommended torque.

Benefits: Prevents filament leaks, ensures efficient thermal transfer to the nozzle, promotes print reliability.

Prerequisites: Basic familiarity with printer maintenance, completed Cold Pull procedure.

¶ Tools & Materials

- 7 mm Wrench (or 7 mm Socket Wrench for the nozzle)

- 12 mm Wrench (or Adjustable Wrench for holding the heater block)

- Torque Wrench (with 7 mm socket, Optional but recommended)

- Heat-Resistant Gloves (Mandatory)

¶ Safety & Pre-checks

Warning: Hotend components reach extremely high temperatures. ALWAYS wear heat-resistant gloves when working near the hotend during this procedure. Failure to do so can result in severe burns.

Warning: Ensure filament has been COMPLETELY removed from the hotend using the Cold Pull method before proceeding to heat the hotend for tightening. Residual filament can burn and cause clogs.

Caution: Use the correct size wrenches and apply force carefully. Support the heater block firmly while turning the nozzle to avoid damaging the hotend assembly or wiring. Do NOT overtighten the nozzle, as this can strip threads or damage the nozzle/heatbreak.

- Confirm filament has been successfully removed via Cold Pull.

- Gather all necessary tools and safety gear.

- Ensure the printer is stable and you have clear access to the hotend.

¶ Step-by-Step Instructions

¶ 1. Filament Removal (Critical Prerequisite)

- Why it's critical: Before heating the hotend for tightening, all filament must be removed from the melt path. If filament remains, heating it without extrusion can cause it to expand, degrade, burn, and solidify, leading to a difficult-to-clear clog in the nozzle and heatbreak.

- Action: Perform a Cold Pull procedure to effectively remove all filament residue from the nozzle and hotend internals.

- Reference: Follow the detailed instructions in the Cold Pull Procedure Guide. Do not proceed until you are confident the hotend is clear of filament.

¶ 2. Heating the Hotend

Once the filament is removed, you need to heat the hotend to allow the metal components to expand before tightening the nozzle..

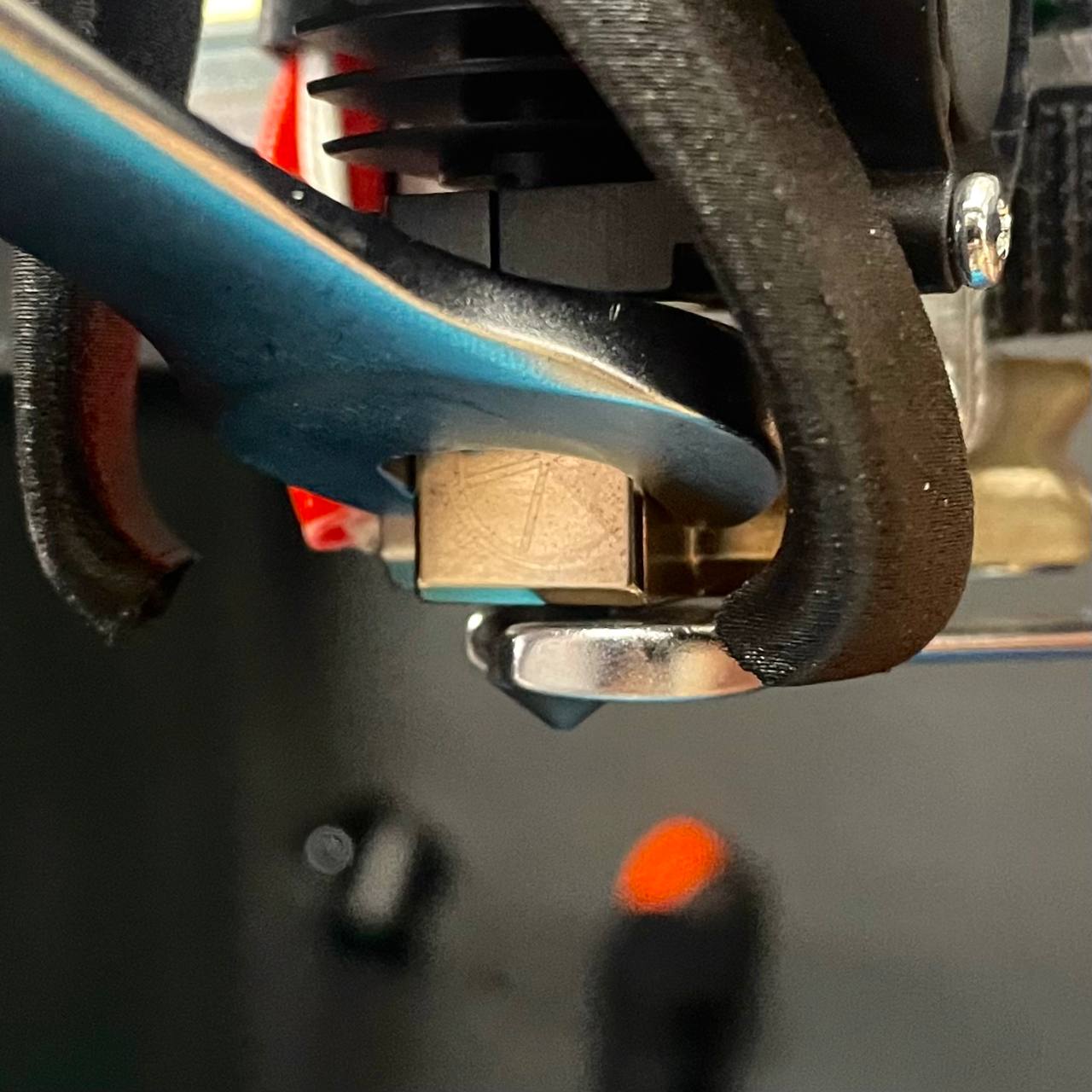

¶ 3. Tightening the Nozzle

This is the safest and generally recommended method for tightening a nozzle, suitable for routine maintenance or after replacing a nozzle with a clean hotend.

- Set Temperature: From the printer's interface, heat the hotend to approximately

20°Chigher than your typical printing temperature for the last material used (or a high-temperature material like ABS/PC if unsure). For example, if you normally print PETG at260°C, heat to280°C. If you regularly print PEEK at380°C, heat to400°C. - Temperature Soak: Allow the hotend to sit at the target temperature for at least 2 minutes. This ensures all components have reached thermal equilibrium and expanded fully.

- Put on Gloves: Equip your heat-resistant gloves.

- Secure Heater Block: Using the 12 mm Wrench (or adjustable wrench), carefully but firmly grip the heater block. Ensure you have a stable hold and are not putting stress on the wiring or thermistor/heater cartridge.

- Tighten Nozzle: Place the 7 mm Wrench or socket onto the nozzle. Gently turn the wrench clockwise to tighten the nozzle against the heatbreak.

- Apply Torque:

- Using Torque Wrench (Recommended): Tighten to

1.5 Nm. - Without Torque Wrench: Tighten until the nozzle feels snug against the heatbreak. Then, apply a small additional turn (approx. 1/8th to 1/4th of a full rotation). The goal is a firm seal without excessive force. Do not overtighten!

- Using Torque Wrench (Recommended): Tighten to

- Cool Down: Once tightened, you can turn off the hotend heating and allow the assembly to cool down.

¶ Troubleshooting & FAQs

- Q: Filament is leaking from above the nozzle after tightening.

- A: The seal between the nozzle and heatbreak is likely insufficient. This usually means the nozzle wasn't tightened enough, or it wasn't hot enough during tightening. Allow the hotend to cool, clean any leaked filament carefully, then repeat the tightening procedure (Steps 1-3), ensuring adequate temperature soak and proper torque/snugness.

- Q: I think I stripped the threads on the nozzle or heater block.

- A: This typically happens from overtightening. Stop immediately. Do not force it further. Component replacement is likely necessary. Contact Vision Miner support for assistance.

- Q: The nozzle clogged right after I tightened it.

- A: Most likely, filament was not completely removed before heating (see Step 1). Residual filament burned and caused a blockage. Attempt the Cold Pull Procedure again. If unsuccessful, the nozzle may need replacement.

¶ Conclusion & Additional Resources

Correctly tightening your nozzle while hot is crucial for preventing leaks and ensuring print quality. Always prioritize safety by wearing gloves and removing filament before heating. Using the recommended torque ensures a secure seal without damaging components.