¶ Brief Overview

This guide explains the Process-Integral-Derivative (PID) tuning procedure for the heaters (Build Plate, T0 & T1 Heaters) on your 22IDEX. PID tuning calibrates the temperature control algorithm, ensuring stable and accurate temperatures, which is crucial for print quality, consistency, and safety. This process is performed using automated macros provided in the printer's firmware.

¶ Introduction

The PID controller in your printer's firmware is responsible for precisely maintaining the set temperatures for the hotends and the bed heater. It does this by intelligently managing power to the heating elements. Over time, or after changes like replacing a heater cartridge, thermistor, the default PID parameters might no longer be optimal.

Symptoms Indicating a Need for PID Tuning:

- Temperature Oscillations: The temperature graph on the printer's interface shows a consistent "wavy" pattern, where the actual temperature fluctuates rhythmically above and below the target temperature instead of holding steady.

- Significant Temperature Overshoot/Undershoot: When a target temperature is set, the actual temperature might rise far above the target before slowly coming down (overshoot), or it might struggle to reach the target, stabilizing noticeably below it (undershoot).

- Slow to Reach Target Temperature: The heater takes an unusually long time to reach the desired setpoint.

- Frequent Temperature-Related Errors: The printer may frequently report errors such as "Heating failed," "Temperature rising too slowly/quickly," "Temperature too high/low," or other thermal model protection errors.

Proper PID tuning minimizes these issues, leading to more stable temperatures, better print quality, and more reliable printer operation.

¶ Tools & Materials

- Vision Miner 22IDEX Printer (no external tools are required for running the macros).

¶ Safety & Pre-checks

WARNING: PID tuning involves heating components (hotends, bed) to operational or specified tuning temperatures. Ensure there are no flammable materials near the printer during this process.

CRITICAL SAFETY NOTICE: The user MUST actively monitor the printer throughout the entire PID tuning process for each heater. Be prepared to immediately POWER OFF the printer using the main power switch or emergency stop button if temperatures rise uncontrollably far beyond the target, or if any other unsafe condition (e.g., smoke, unusual smells) occurs.

- Ensure you select the correct macro for the specific heater (Bed, Left Hotend/T0, Right Hotend/T1) you intend to tune.

- Ensure the hotend nozzle is clean and the bed surface is clear before starting.

¶ Step-by-Step Instructions

¶ Performing PID Tuning via Macros

The Vision Miner 22IDEX firmware includes automated macros to perform PID tuning for each heating element.

¶ 1. Preparation

-

Start from Ambient Temperature

Before you run any PID tuning macro, verify that the heating element you’re tuning is at true room temperature. -

Bed PID Tuning

- Remove all parts from the build plate.

- Wipe the bed surface clean to ensure accurate temperature readings.

-

Hotend PID Tuning

Run the automatic ColdPull routine to fully retract filament before tuning.

¶ 2. Accessing the PID Tuning Macros

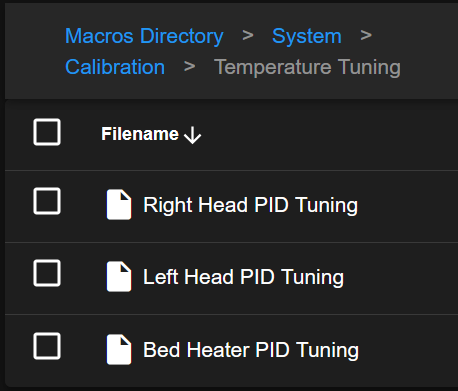

- On the printer's web interface, navigate to the

Macrostab. - Navigate to the

System > Calibration > Temperature Tuningfolder. - Inside this folder, you should find separate macros for each heater.

¶ 3. Running the PID Tuning Macro for a Specific Heater

- Select the macro for the heater you want to tune.

- The macro will prompt you to confirm or enter a target temperature for tuning. This should generally be a higest of most often used temperature for that component.

- Once confirmed, tap to start the selected PID tuning macro.

¶ 4. Monitoring the Automated Process

- The printer will now begin the automated PID tuning cycle. This involves heating the selected component to the target temperature and then cycling the power to it multiple times, allowing the temperature to rise and fall slightly around the setpoint. This process allows the firmware to measure the thermal response of the heater and calculate the optimal P, I, and D parameters.

- This tuning process is fully automatic and can take several minutes to complete for each heater.

CRUCIAL USER ACTION: You MUST actively watch the printer and its temperature graph/readings on the screen throughout the entire tuning cycle.

If you observe the temperature rising uncontrollably, exceeding the target by a large margin, if you notice any other signs of malfunction such as smoke, unusual smells, or error messages indicating a thermal runaway, IMMEDIATELY POWER OFF THE PRINTER using the main power switch or emergency stop.

¶ 5. Completion and Saving Parameters

- Once the PID tuning cycle for the selected heater is complete, the printer will typically display a message on the screen, such as "PID Tuning successful" or similar.

- The newly calculated PID parameters for that heater are usually saved automatically to the printer's configuration file.

¶ Verification (After Tuning)

- After completing PID tuning for a heater, it's good practice to verify its performance.

- Set the tuned heater to a typical operating temperature.

- Observe the temperature graph on the printer's interface. The temperature should:

- Rise smoothly to the target.

- Have minimal overshoot (not going much higher than the target).

- Settle quickly and remain stable at the target temperature with very little fluctuation (a smooth, flat line once stable).

If the temperature behavior is significantly improved and stable, the PID tuning was successful.

¶ Troubleshooting & FAQs

- Q: The temperature still oscillates significantly after PID tuning.

- A: Try running the PID tuning macro again for that heater. Ensure the printing environment is stable during the tune (e.g., avoid strong drafts hitting the hotend if it's being tuned without an enclosure, or ensure the enclosure door is closed if tuning with it).

- Q: The PID tuning macro fails to complete, or the printer reports errors during the tuning process.

- A: This could indicate an issue with the heater cartridge, thermistor, or their wiring (e.g., loose connections, intermittent faults). Check all relevant connections carefully. If problems persist, there might be a hardware issue requiring further investigation or component replacement. Contact support.

- Q: Do I need to PID tune often?

- A: Not typically. PID tuning is usually done when initially setting up the printer, after replacing heating components (heater cartridge, thermistor, control board), after a major firmware update that affects PID logic, or if you notice persistent temperature instability symptoms.

¶ Conclusion & Additional Resources

Well-tuned PID parameters are vital for achieving consistent extrusion, good layer adhesion, and overall print quality, as well as contributing to the safe operation of your printer. The automated macros simplify this important calibration step. Always monitor the process closely for safety.