¶ Brief Overview

This guide provides step-by-step instructions for replacing three critical temperature sensors on the Vision Miner 22IDEX 3D printer: the Bed Temperature Sensor, the Chamber Heater Temperature Sensor, and the Chamber Temperature Sensor. Properly functioning sensors are essential for accurate temperature control, print quality, and overall printer safety. These procedures outline the necessary tools, safety precautions, and detailed steps for successful sensor replacement.

¶ Introduction

The Vision Miner 22IDEX utilizes multiple temperature sensors for precise thermal management during printing operations. This document covers the replacement procedures for the sensors located in the print bed, the chamber heater assembly, and within the build chamber itself. Following these instructions carefully will help ensure the continued reliability and performance of your printer.

Scope: This guide details the removal of the old sensor and the installation of a new one for the Bed, Chamber Heater, and Chamber sensors.

Benefits: Replacing a faulty sensor restores accurate temperature monitoring and control, preventing print failures and potential damage.

Prerequisites: Basic familiarity with hand tools and printer components. Ensure you have the correct replacement sensor part before beginning.

The replacement procedure for the Head Temperature Sensor is detailed separately here.

¶ 1. Replacing the Bed Temperature Sensor

¶ 1.1 Brief Overview

This section details how to replace the temperature sensor located underneath the print bed. This sensor monitors the bed's surface temperature, crucial for print adhesion and material properties.

¶ 1.2 Tools & Materials

- Replacement Bed Sensor

- 2 mm Hex Driver

- 5.5 mm Wrench (or Pliers)

- Wire Cutters (or Flush Cutters)

- Tweezers (fine tip)

- Tape (e.g., Electrical tape)

- Thermal Paste (e.g., Boron Nitride paste)

- Zip Ties (small)

¶ 1.3 Safety & Pre-checks

Warning: Always power off the printer and unplug the power cord from the mains outlet before performing any maintenance. Allow all components, especially the print bed, to cool down completely to room temperature to avoid burns.

- Verify the printer is powered off and unplugged.

- Confirm the print bed is cool to the touch.

- Gather all required tools and the new replacement sensor.

- Ensure you have adequate lighting and workspace around the printer.

¶ 1.4 Step-by-Step Instructions

¶ 1.4.1 Prepare the Printer

- Ensure the printer has cooled down completely to room temperature.

- Power off the printer using the main switch.

- Disconnect the power cord from the wall outlet.

¶ 1.4.2 Access the Bed Sensor

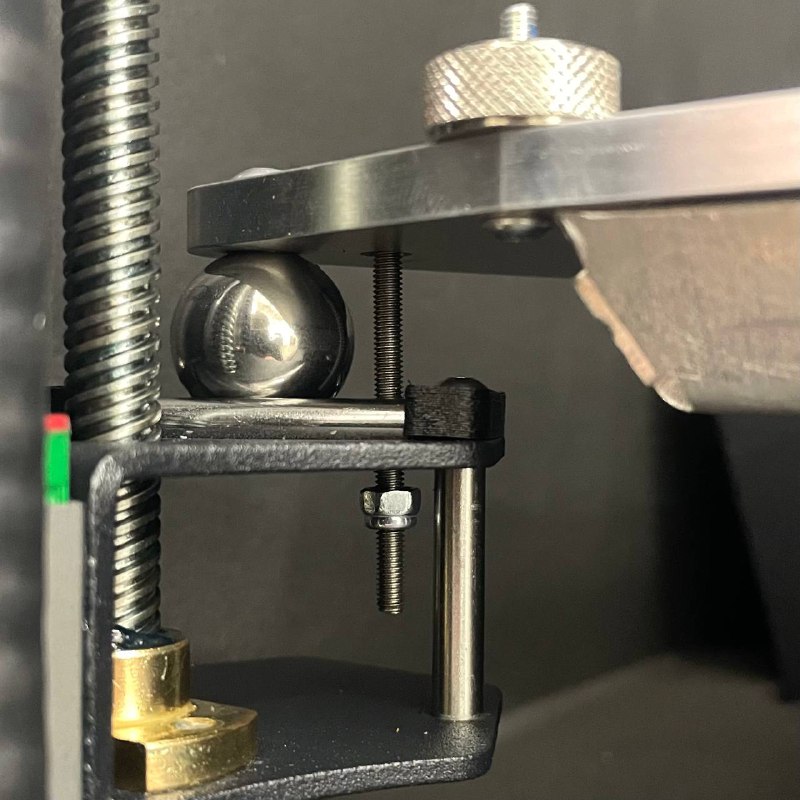

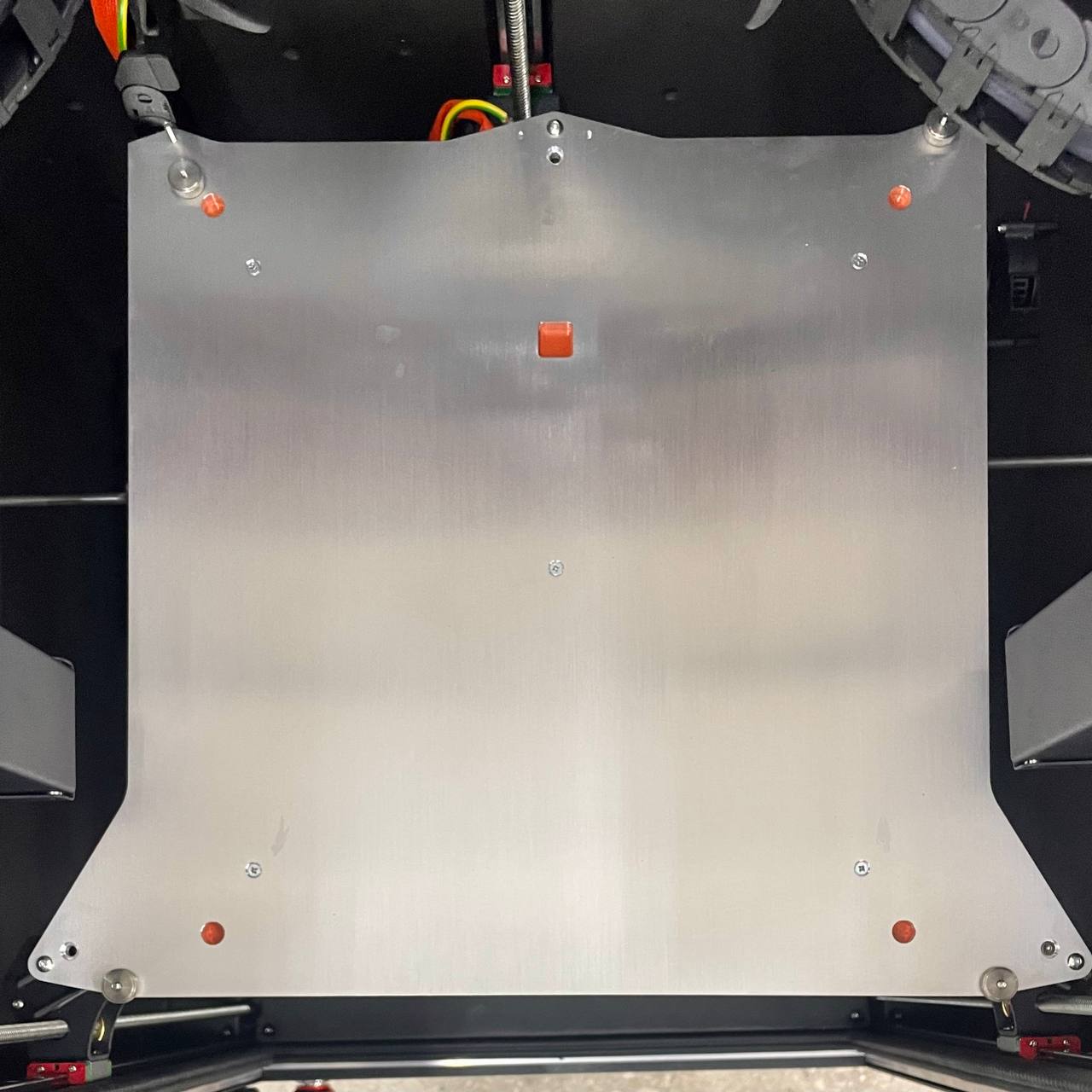

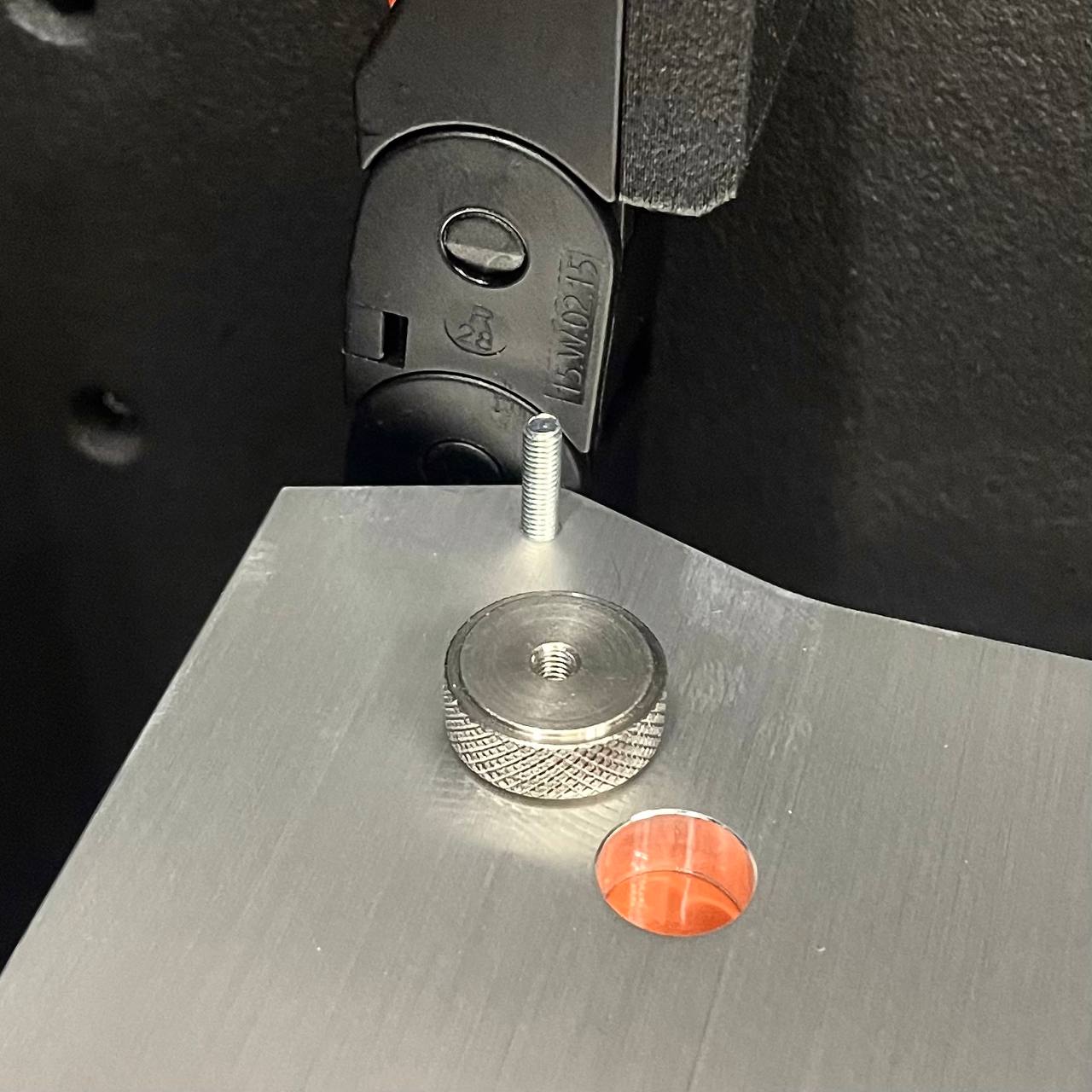

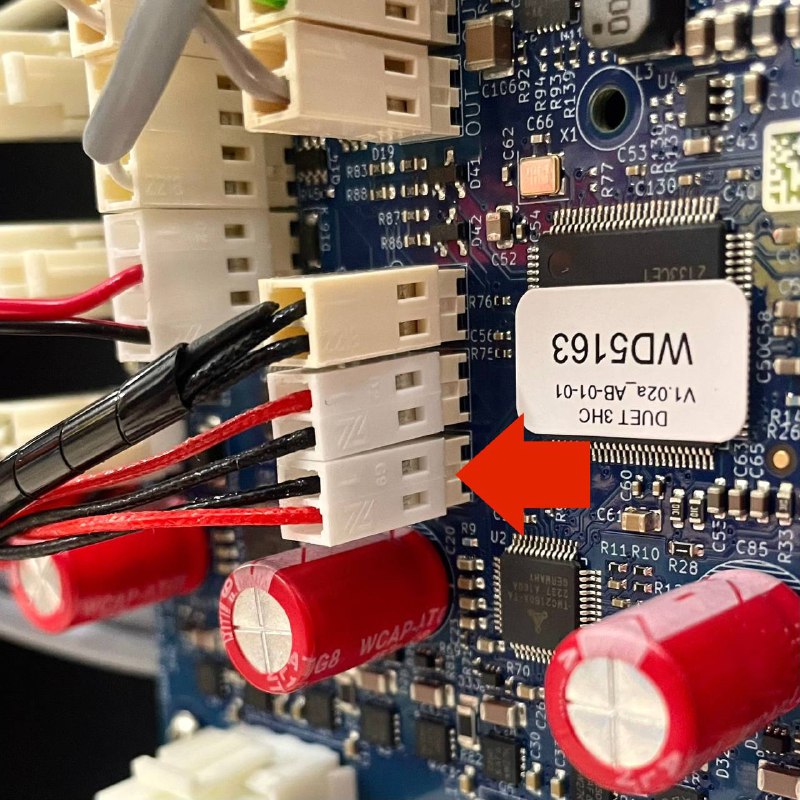

- Unscrew Bed Screws: Using a 5.5 mm Wrench and 2 mm Hex Driver unscrew the front left bed mounting screw and the rear center bed mounting screw.

- Remove Rear Left Bed Holding Nut: Completely unscrew and remove the nut securing the rear left corner of the build plate.

- Displace the Bed: Carefully lift the left side of the bed slightly and slide the entire bed assembly carefully towards the right and slightly forward to gain access to the sensor mounting location underneath. Be cautious not to strain any wires.

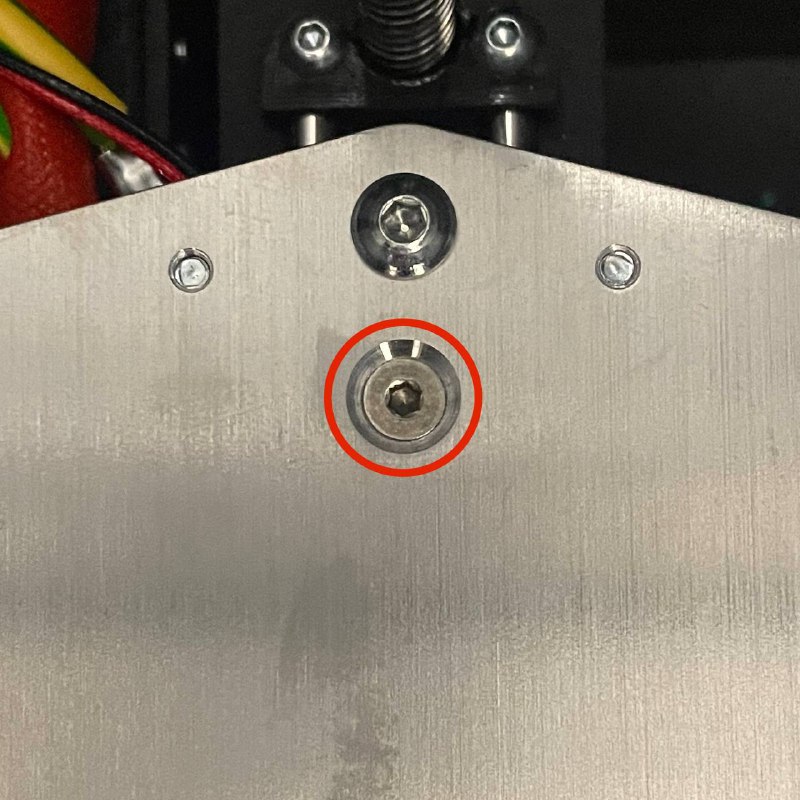

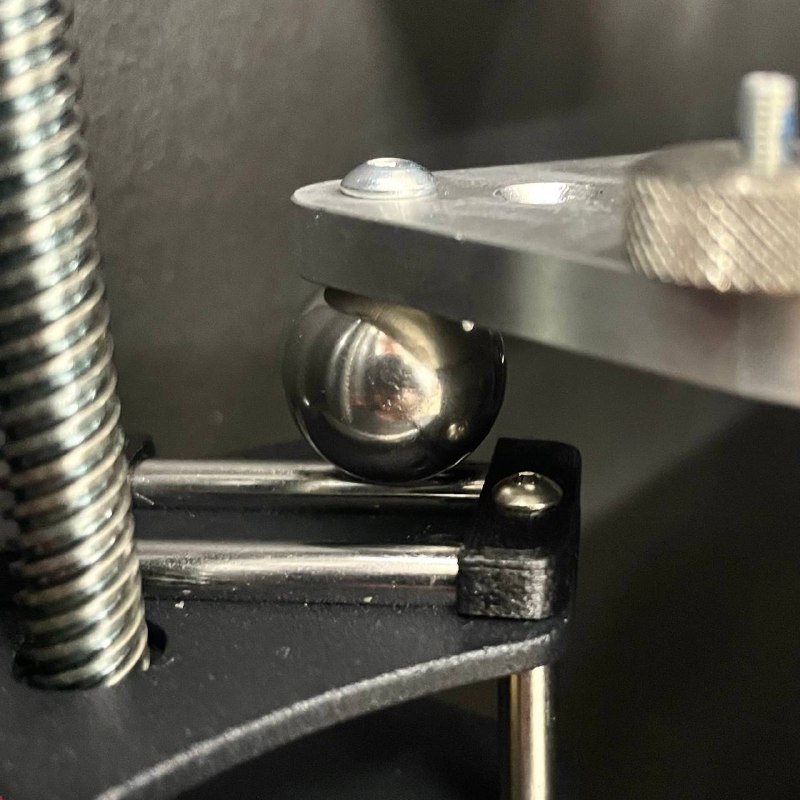

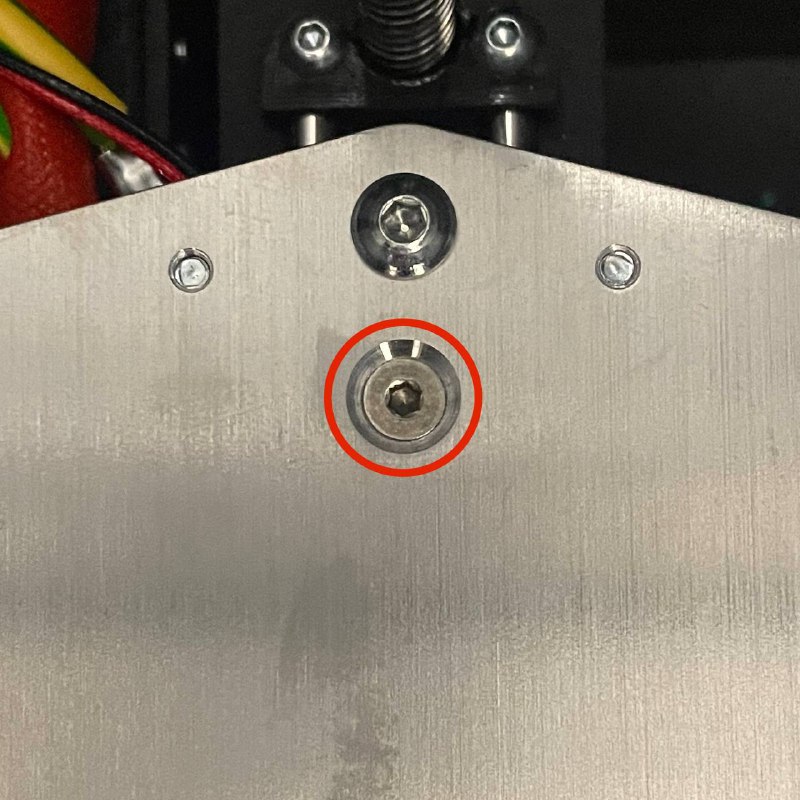

- Unscrew Sensor: Locate the bed temperature sensor secured underneath the bed plate. Use a 2 mm Hex Driver to remove the screw holding the sensor in place. Carefully set the screw aside.

¶ 1.4.3 Route and Replace the Sensor

- Access Wiring: Open the rear access doors of the printer.

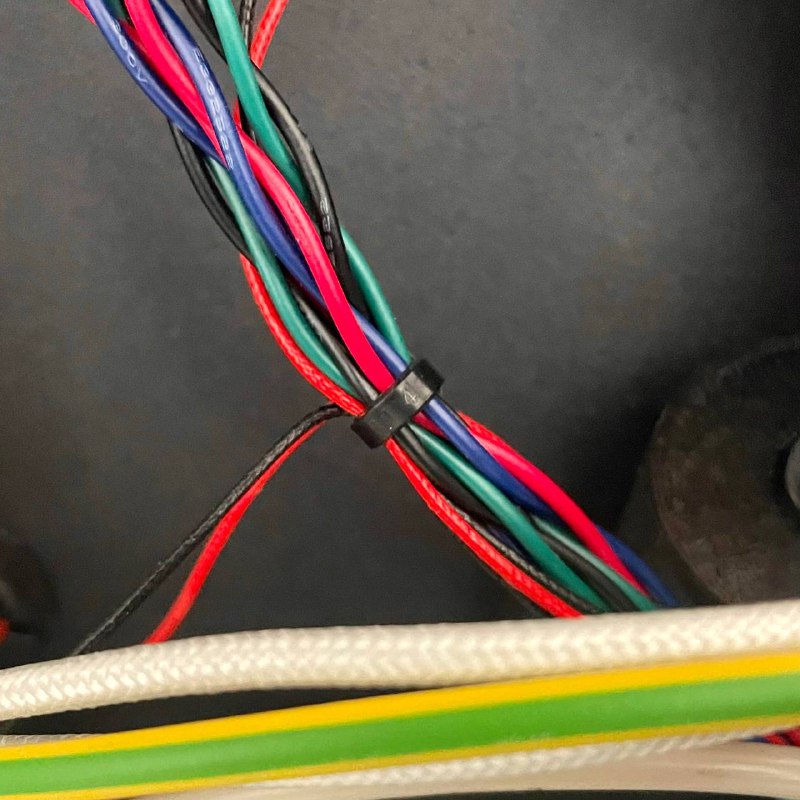

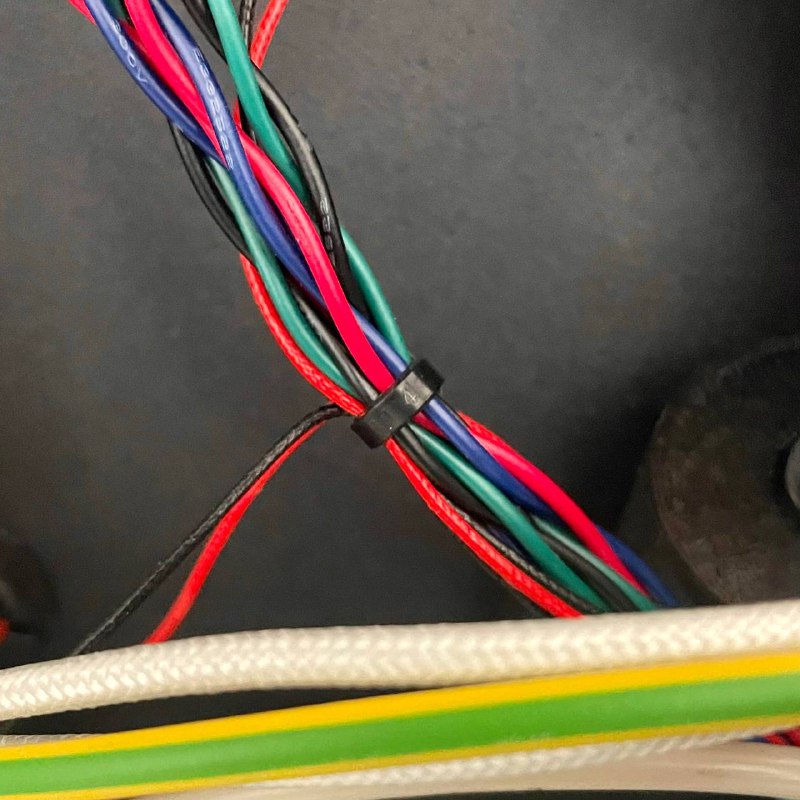

- Cut Zip Ties: Carefully locate the bed temperature sensor cable within the wiring loom. Using Wire Cutters, snip the zip ties securing the sensor cable. Be extremely careful not to cut any other wires.

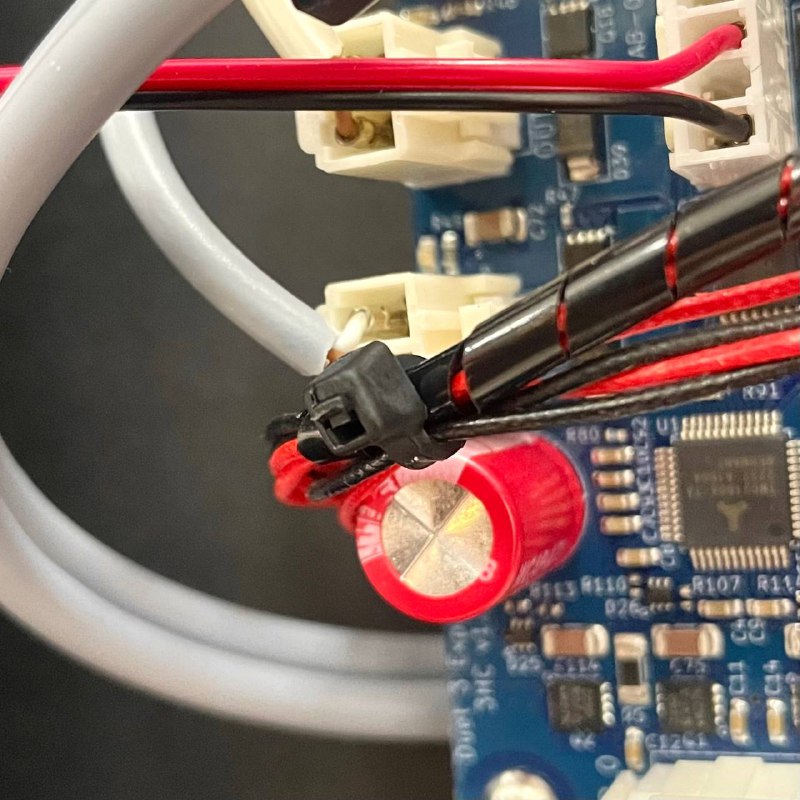

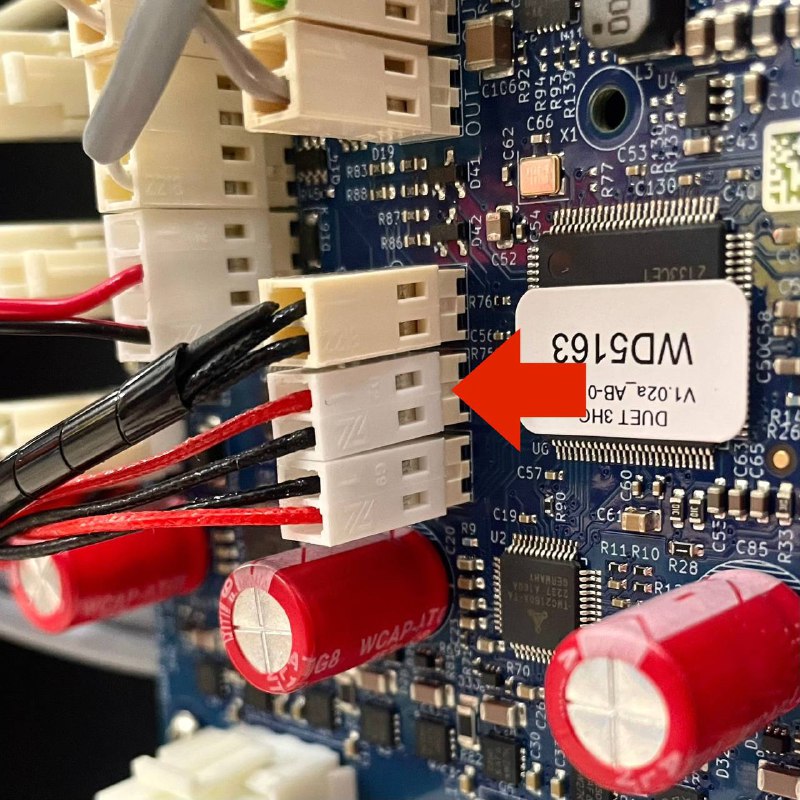

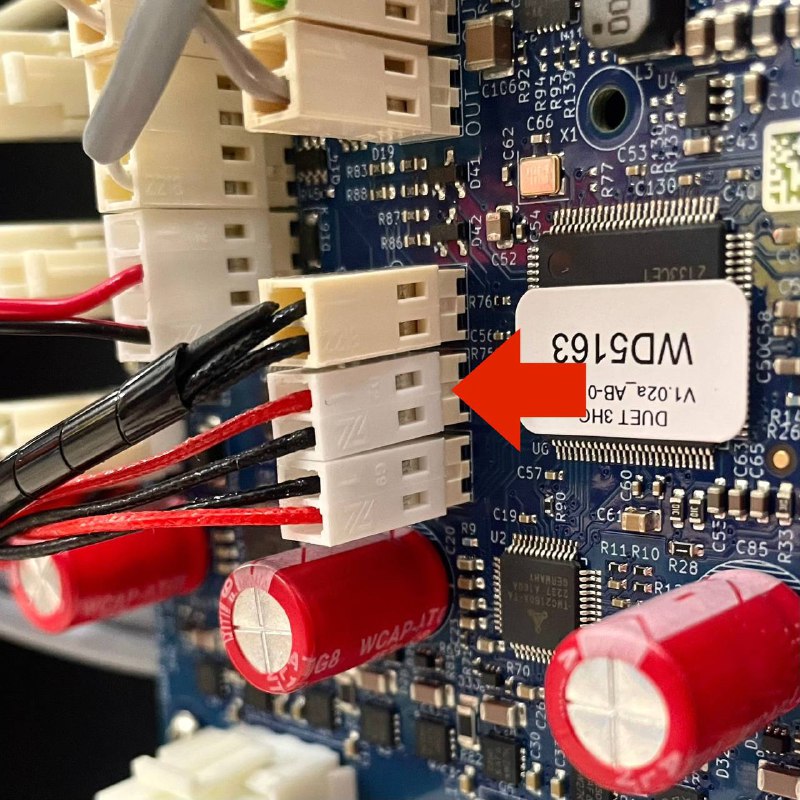

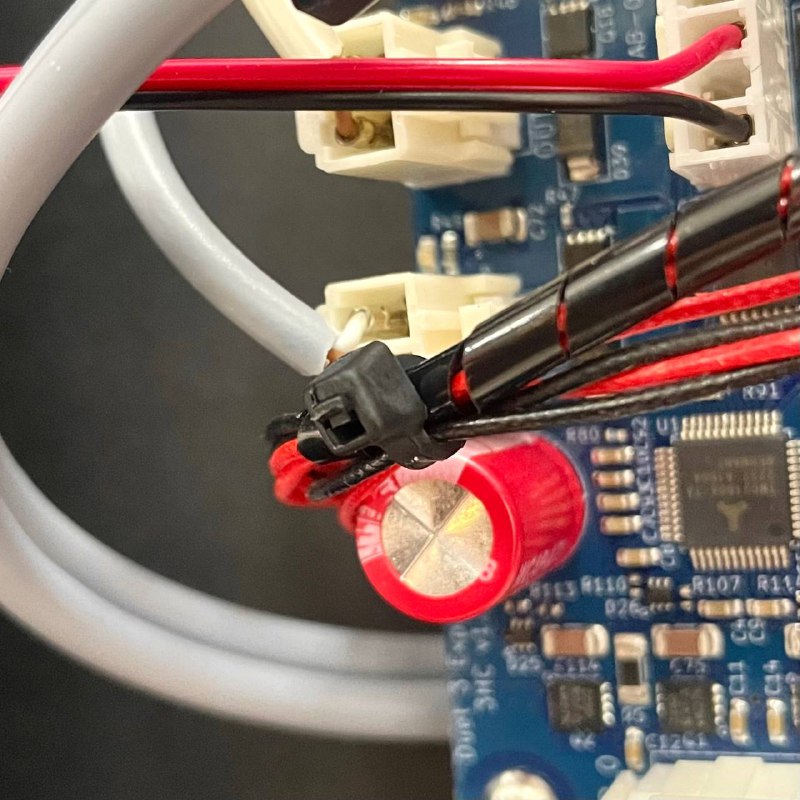

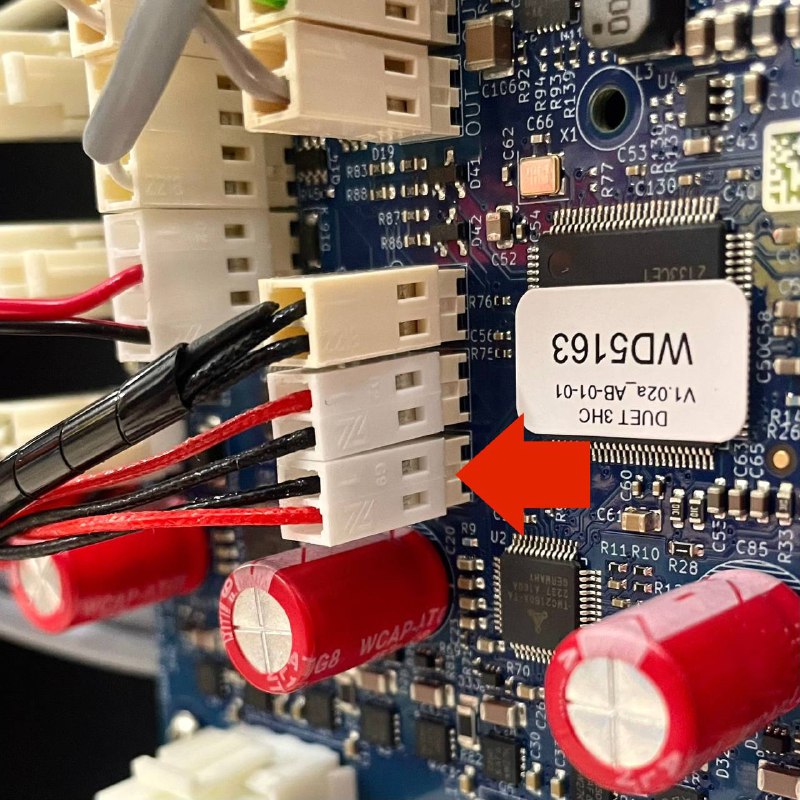

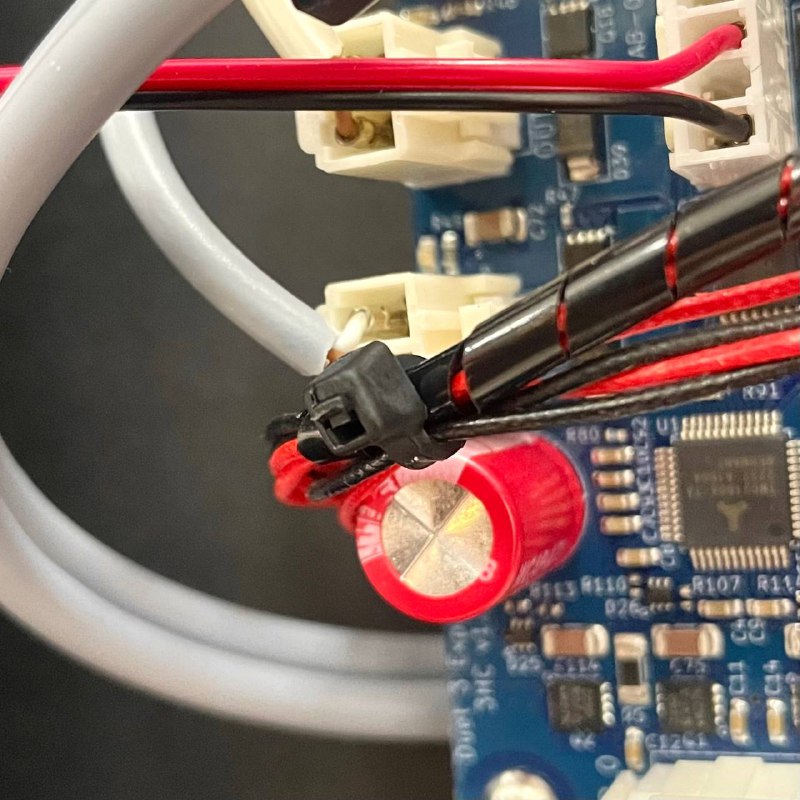

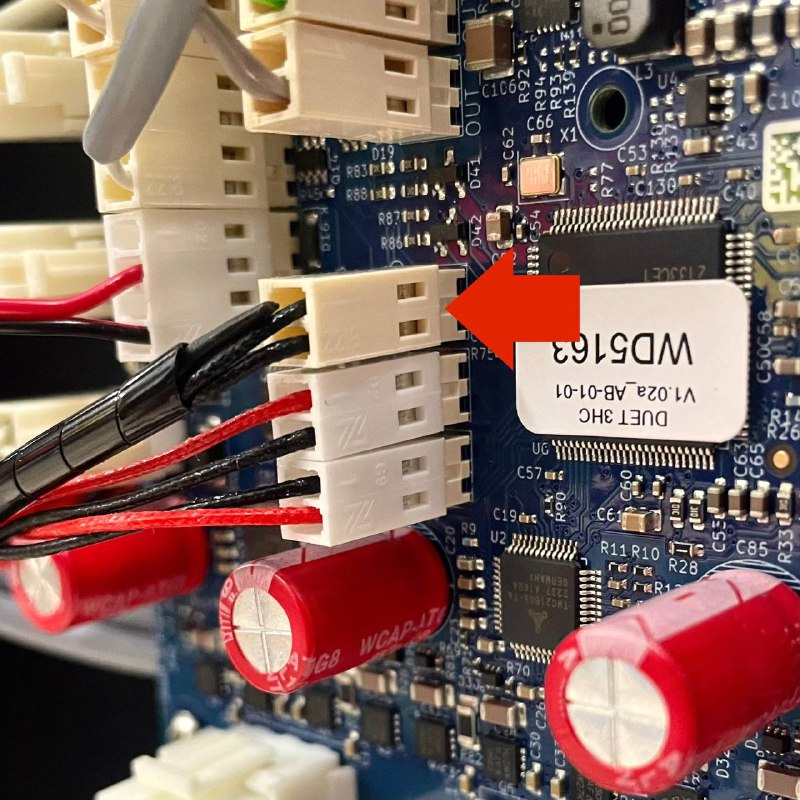

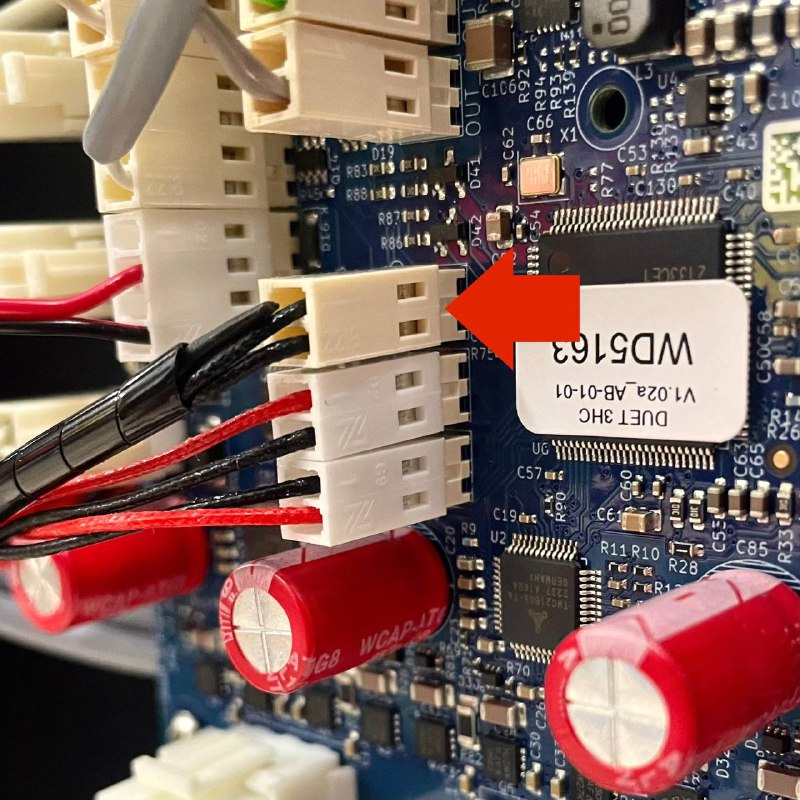

- Disconnect Sensor: Trace the sensor cable to the mainboard. Identify the bed thermistor connector (refer to Wiring Schematic if unsure) and carefully unplug it from the board.

- Attach New Sensor: Cutt off the connector from the old sensor, firmly tie the wires to the end of the new sensor (the sensor end), and wrap the connection with tape. Ensure the connection is smooth and strong enough to be pulled through cable channels without snagging or separating.

- Pull New Sensor Wire: Gently pull the old sensor wire out, guiding the new sensor wire along the same path through the rear compartment to the bed plate. Pull slowly and steadily. If you encounter resistance, check for snags. Removing cable channel covers temporarily can aid in guiding the wire.

Tip: Avoid excessive force, which could damage the new sensor's wiring.

- Disconnect Old Sensor: Once the new sensor wire is fully routed through the rear compartment and bed cable channel, remove the tape and separate the old sensor from the new one.

- Connect New Sensor: Plug the new connector directly into the appropriate socket on the mainboard.

¶ 1.4.4 Reassembly and Testing

- Apply Thermal Paste: Apply a small amount of Thermal Paste to the metal casing of the new sensor head. This ensures good thermal contact with the bed plate.

- Mount Sensor: Position the new sensor back into its mounting location under the bed plate and secure it using the 2 mm Hex Driver and the screw removed earlier. Do not overtighten.

- Position Bed: Carefully slide the bed assembly back to its original position.

- Secure Bed:

- Reinstall the rear left bed nut using Pliers or a wrench.

- Screw the front left and rear center adjustment screws using the 5.5 mm Wrench and 2 mm Hex Driver.

- Reinstall the rear left bed nut using Pliers or a wrench.

Important: Bed leveling will be required after this procedure.

- Secure Wiring: In the rear compartment, neatly route the new sensor cable alongside other wiring and secure it using new Zip Ties. Ensure cables are not pinched or strained.

- Final Checks: Close the rear access doors. Plug the power cord back into the outlet.

- Test Sensor: Power on the printer. Navigate to the heating controls on the web interface. Start heating the bed (e.g., set to

60°C). Monitor the temperature reading to ensure it rises steadily and accurately reflects the target temperature.

¶ 1.5 Troubleshooting & FAQs

- Q: Bed temperature reads

-200°CorLowerafter replacement.- A: Check the sensor connection at the mainboard. Ensure it's fully seated in the correct port. Verify wires were inserted correctly into the connector housing if de-pinned. Inspect the wire for damage along its path.

- Q: Bed temperature reading is inaccurate or unstable.

- A: Check the sensor connection at the mainboard. Ensure it's fully seated in the correct port. Verify wires were inserted correctly into the connector housing if de-pinned. Inspect the wire for damage along its path.

- Q: Difficulty pulling the new wire through.

- A: Check for snags in the cable path. Temporarily remove cable channel covers for better visibility and manual guidance. Ensure the taped connection between old and new wires is smooth and slim.

¶ 1.6 Conclusion & Additional Resources

You have successfully replaced the bed temperature sensor. Remember to perform a full bed leveling procedure before starting your next print.

¶ 2. Replacing the Chamber Heater Temperature Sensor

¶ 2.1 Brief Overview

This section describes how to replace the temperature sensor associated with the chamber heater element. This sensor monitors the heater's temperature, ensuring the build chamber reaches and maintains the desired ambient temperature for specific materials.

¶ 2.2 Tools & Materials

- Replacement Chamber Heater Sensor

- PH2 Phillips Screwdriver

- Wire Cutters (or Flush Cutters)

- Tweezers (fine tip)

- Tape (e.g., Electrical tape)

- Thermal Paste (e.g., Boron Nitride paste)

- Zip Ties (small)

¶ 2.3 Safety & Pre-checks

Warning: Always power off the printer and unplug the power cord before maintenance. Allow the chamber heater element and surrounding areas to cool completely. The heater can reach high temperatures.

Caution: Accessing the chamber heater requires careful positioning of the printer. Ensure it is stable and secure before working underneath it.

- Verify the printer is powered off, unplugged, and fully cooled.

- Gather all required tools and the new replacement sensor.

- Prepare a stable way to access the underside of the chamber heater (e.g., place the printer on a sturdy stand or carefully position it on the edge of a table as described).

¶ 2.4 Step-by-Step Instructions

¶ 2.4.1 Prepare the Printer

- Ensure the printer has cooled down completely to room temperature.

- Power off the printer using the main switch.

- Disconnect the power cord from the wall outlet.

- Position Printer for Access: Carefully position the printer to allow access to the screws underneath the chamber heater assembly located at the left rear of the build chamber.

- Option A: Place the printer securely on a raised stand or blocks.

- Option B: Carefully slide the printer partially off a sturdy table edge so it rests stably on three feet, providing clearance underneath the chamber heater area. Ensure the printer cannot tip over.

¶ 2.4.2 Access the Chamber Heater Sensor

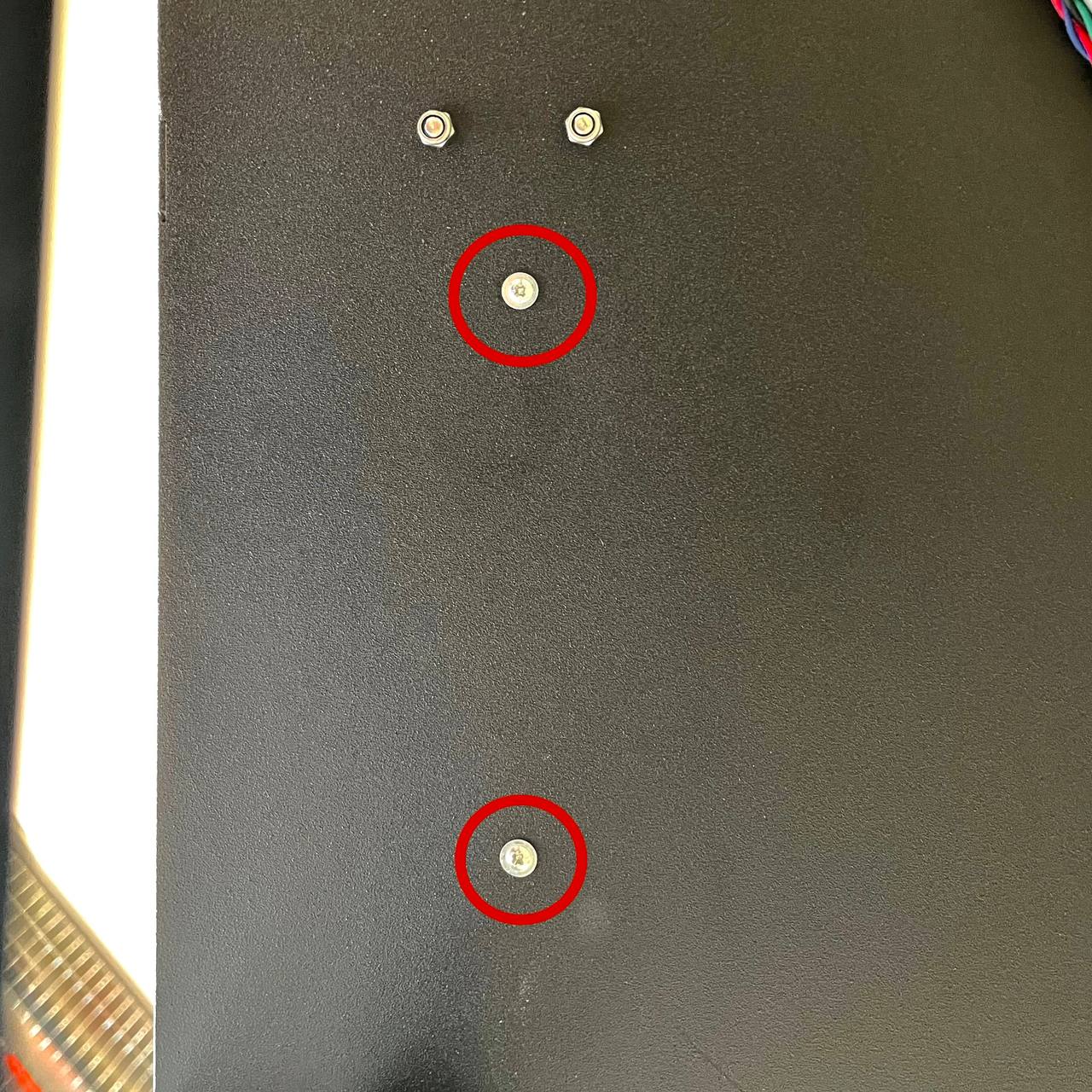

- Unscrew Heater Assembly: Using a PH2 Phillips Screwdriver, unscrew the mounting screws securing the entire chamber heater assembly to the printer frame. This may provide better access to the sensor screw.

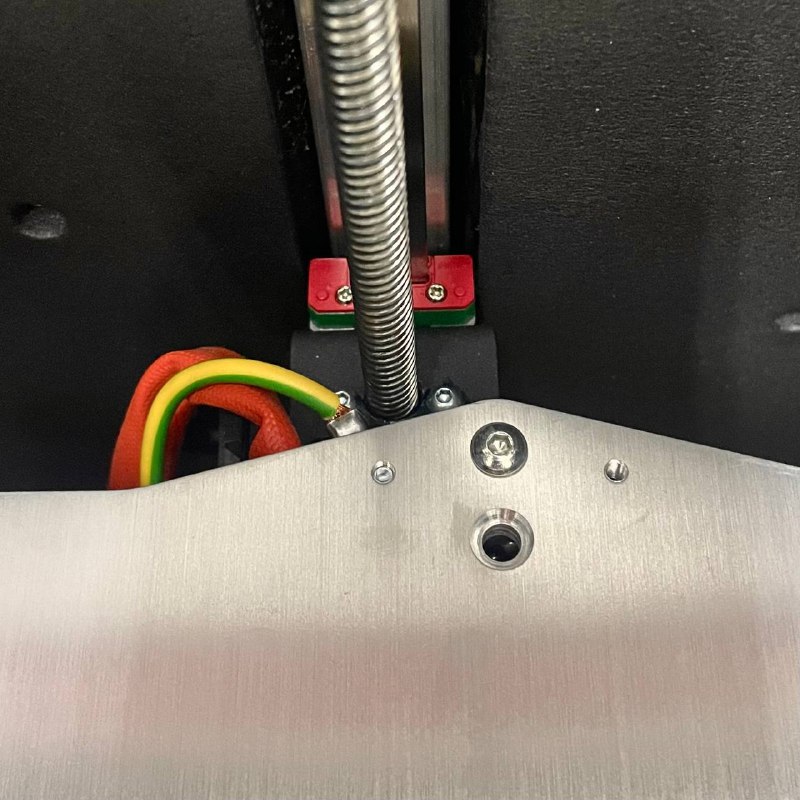

- Unscrew Sensor: Locate the temperature sensor attached to the chamber heater element. Using a PH2 Phillips Screwdriver, carefully unscrew the sensor from its mounting point on the heater block.

¶ 2.4.3 Route and Replace the Sensor

- Access Wiring: Open the rear access doors of the printer.

- Cut Zip Ties: Carefully locate the chamber heater sensor cable. Using Wire Cutters, snip the zip ties securing this specific sensor cable. Avoid cutting other wires.

- Disconnect Sensor: Trace the sensor cable to the mainboard. Identify the chamber heater thermistor connector (refer to Wiring Schematic if unsure) and carefully unplug it from the board.

- Attach New Sensor: Cutt off the connector from the old sensor, firmly tie the wires to the end of the new sensor (the sensor end), and wrap the connection with tape. Ensure the connection is smooth and strong enough to be pulled through cable channels without snagging or separating.

- Pull New Sensor Wire: Gently pull the old sensor wire out, guiding the new sensor wire along the same path through the rear compartment to the chamber heater assembly. Pull slowly and steadily. If you encounter resistance, check for snags. Removing cable channel covers temporarily can aid in guiding the wire.

Tip: Avoid excessive force, which could damage the new sensor's wiring.

- Disconnect Old Sensor: Remove the tape and separate the old sensor from the new one once routed.

- Connect New Sensor: Plug the new connector directly into the appropriate socket on the mainboard.

¶ 2.4.4 Reassembly and Testing

- Apply Thermal Paste: Apply a small amount of Thermal Paste to the metal surface of the new sensor.

- Mount Sensor: Carefully screw the new sensor back into its mounting point on the chamber heater element using the PH2 Phillips Screwdriver. Ensure it is snug but do not overtighten.

- Secure Heater Assembly: Screw the chamber heater assembly mounting screws using the PH2 Phillips Screwdriver.

- Secure Wiring: Route the new sensor cable neatly in the rear compartment and secure with new Zip Ties.

- Final Checks: Return the printer to its normal operating position. Close the rear access doors. Plug in the power cord.

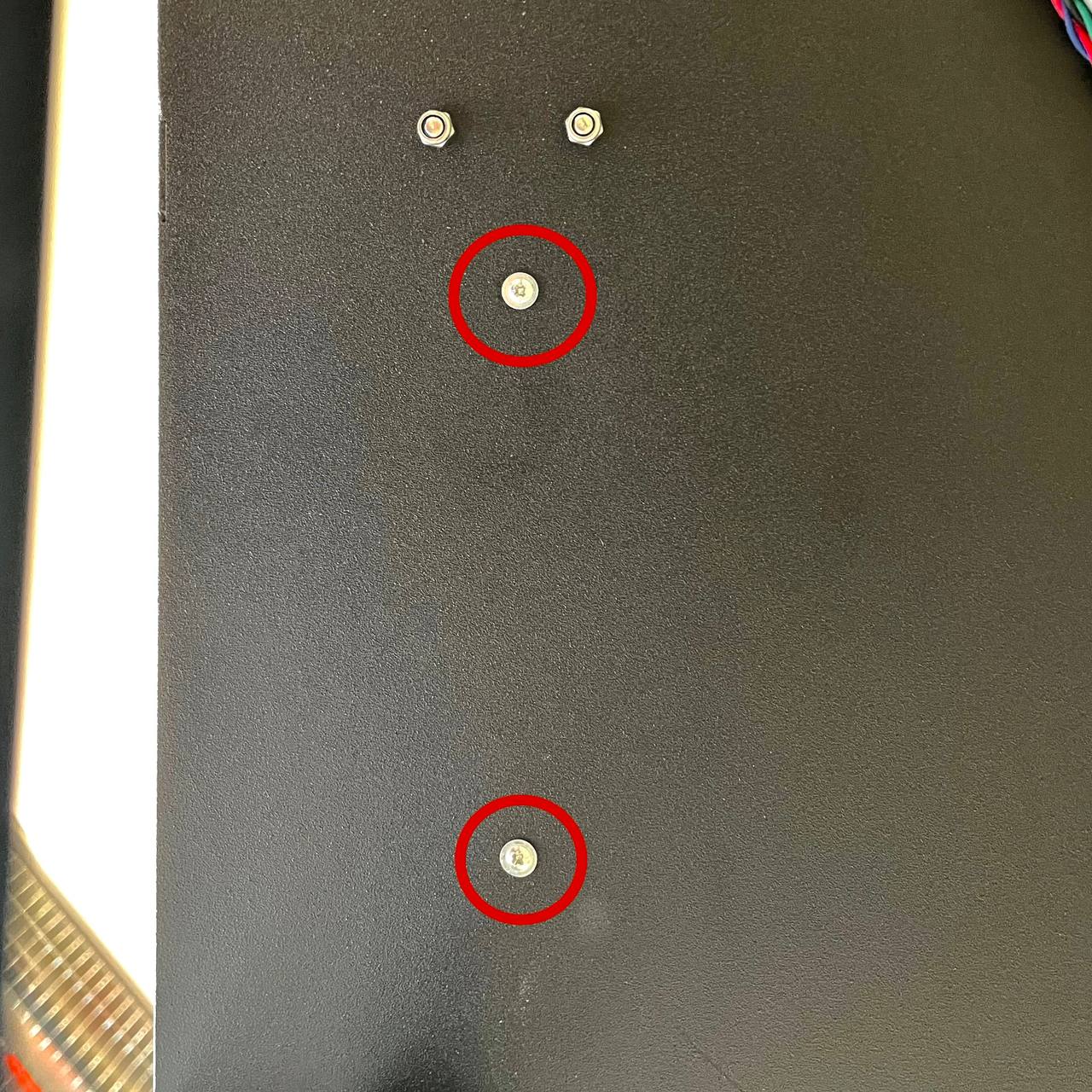

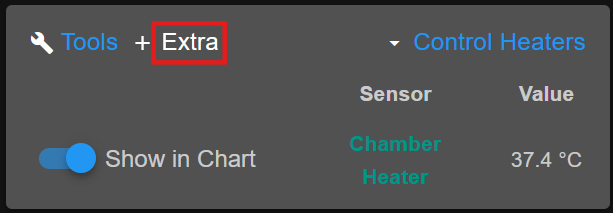

- Test Sensor: Power on the printer. Navigate to the Extra tab or heating controls. Start heating the chamber (e.g., set to

50°C). Monitor the temperature reading to ensure it rises correctly and stabilizes near the target.

¶ 2.5 Troubleshooting & FAQs

- Q: Chamber Heater temperature reads

-200°CorLowerafter replacement.- A: Check the sensor connection at the mainboard. Ensure it's fully seated in the correct port. Verify wires were inserted correctly into the connector housing if de-pinned. Inspect the wire for damage along its path.

- Q: Chamber Heater temperature reading is inaccurate or unstable.

- A: Check the sensor connection at the mainboard. Ensure it's fully seated in the correct port. Verify wires were inserted correctly into the connector housing if de-pinned. Inspect the wire for damage along its path.

- Q: Difficulty pulling the new wire through.

- A: Check for snags in the cable path. Temporarily remove cable channel covers for better visibility and manual guidance. Ensure the taped connection between old and new wires is smooth and slim.

¶ 2.6 Conclusion & Additional Resources

The chamber heater temperature sensor has been replaced. Accurate chamber heating is now restored.

¶ 3. Replacing the Chamber Temperature Sensors

¶ 3.1 Brief Overview

This section explains how to replace the ambient temperature sensors located within the build chamber. These sensors monitor the air temperature inside the enclosure, distinct from the build plate or heater element temperatures.

¶ 3.2 Tools & Materials

- Replacement Chamber Sensors

- Hammer (small)

- Drift Punch Tool (approx. 6 mm diameter, or similar sturdy rod/screw)

- Wire Cutters (or Flush Cutters)

- Tweezers (fine tip)

- Tape (e.g., Electrical tape)

- Zip Ties (small)

- Replacement Printed Sensor Holders (Optional, but highly recommended.) Download Holders Here

¶ 3.3 Safety & Pre-checks

Warning: Always power off the printer and unplug the power cord before maintenance. Allow the printer to cool completely. Exercise caution when using the hammer and punch tool to avoid damaging the printer chassis or injuring yourself.

- Verify the printer is powered off, unplugged, and cool.

- Gather all required tools and the new replacement sensors.

- If possible, print the replacement Sensor Holders beforehand using a high-temperature material(e.g. Nylon CF or GF).

¶ 3.4 Step-by-Step Instructions

¶ 3.4.1 Prepare the Printer

- Ensure the printer has cooled down completely.

- Power off the printer and disconnect the power cord.

- Open the main printer door for access to the build chamber.

¶ 3.4.2 Remove Old Sensors and Holders

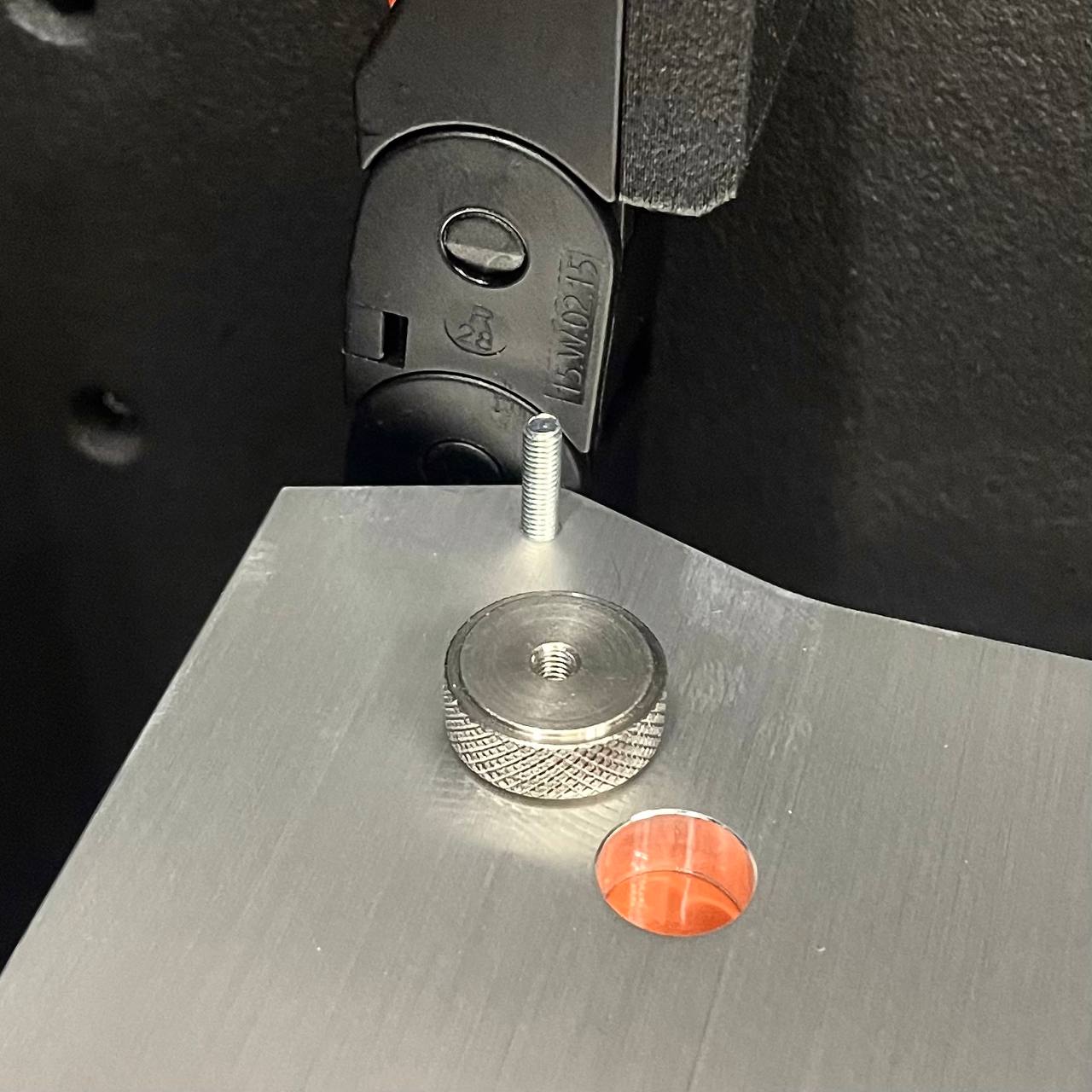

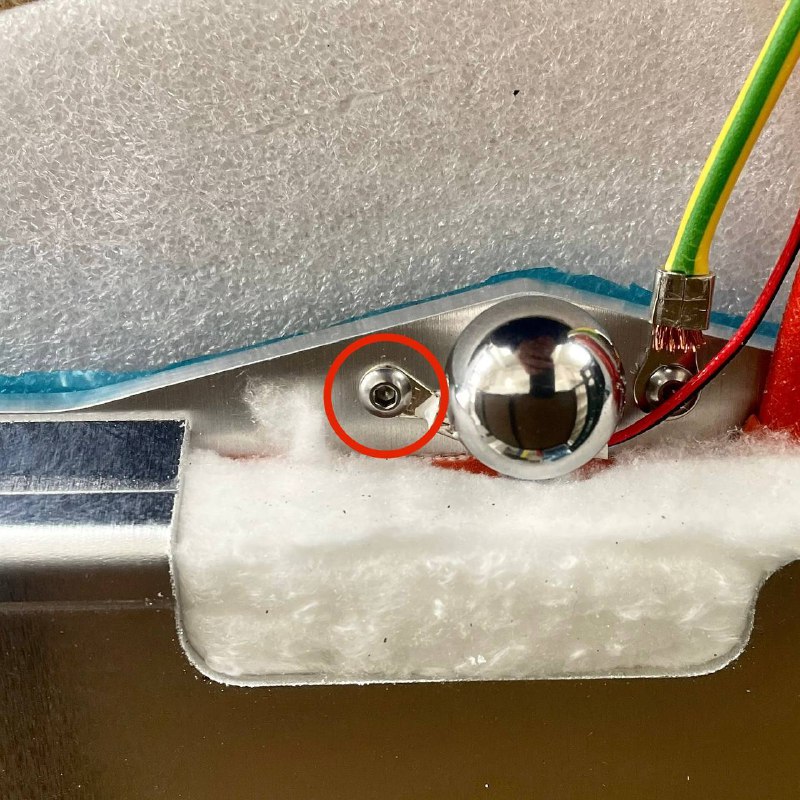

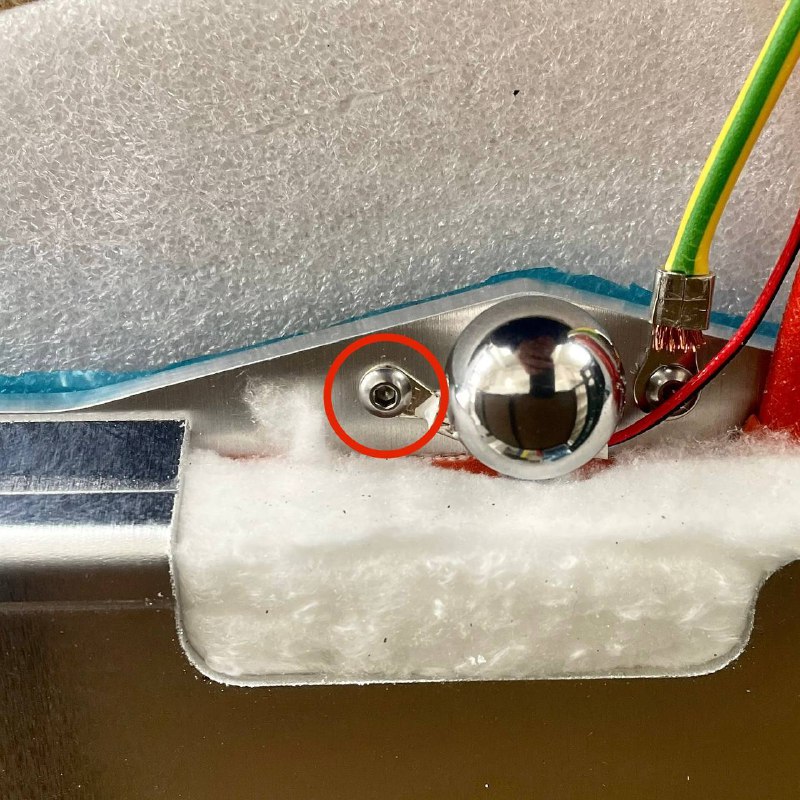

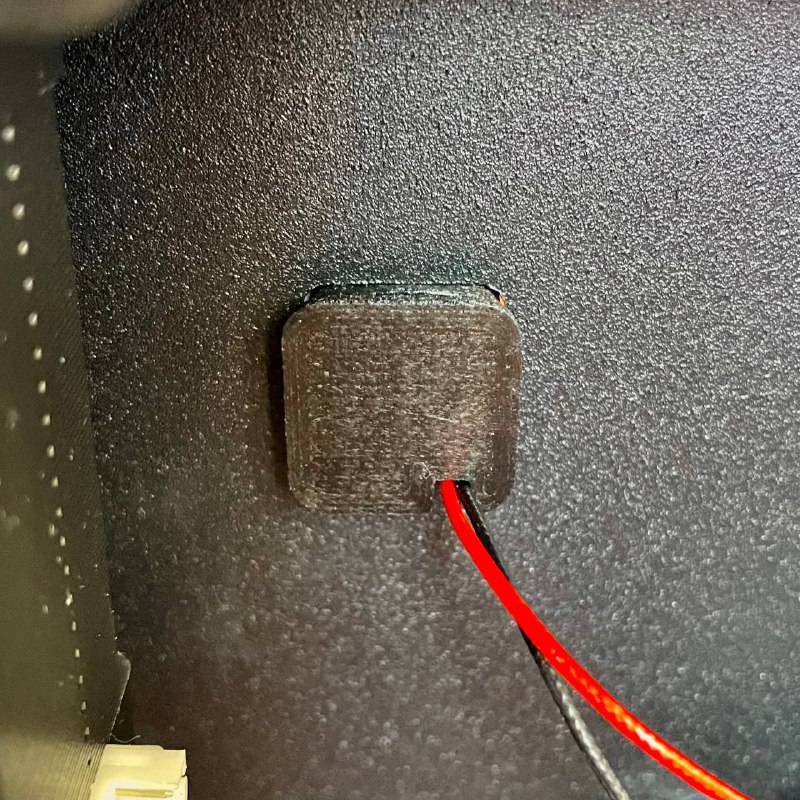

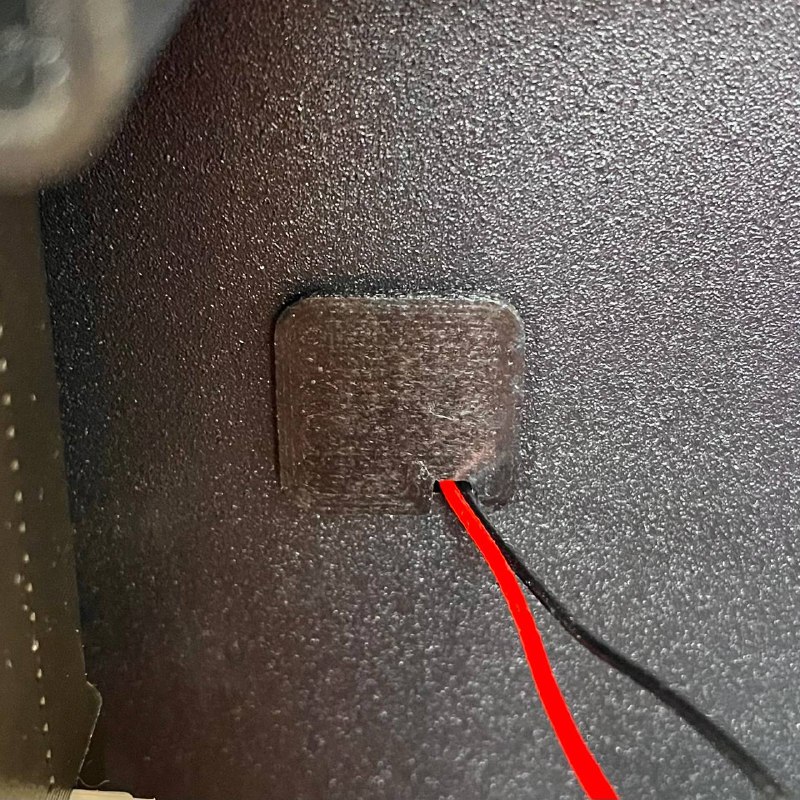

- Release Sensors: Locate the chamber temperature sensors mounted inside the chamber. Carefully unclip or slide the sensor bulb/tip from its printed holder. Let it hang freely for now.

- Remove Holders: Place the Drift Punch Tool against the base of the printed sensor holder where it inserts into the printer's chassis/wall. Using the Hammer, give the punch firm but controlled taps to push the holder out from the inside of the chamber towards the outside. Remove all holders.

Caution: Tap gently and progressively to avoid damaging the printer wall. Support the area from the other side if possible.

¶ 3.4.3 Route and Replace the Sensor

- Access Wiring: Open the rear access doors.

- Cut Zip Ties: Locate the chamber sensor cables. Using Wire Cutters, carefully snip the securing zip ties.

- Disconnect Sensor: Trace the sensor cables to the mainboard. Identify the chamber thermistor connector (refer to Wiring Schematic if unsure) and carefully unplug it from the board.

- Attach New Sensors: Attach New Sensor: Cutt off the connectors from the old sensors, firmly tie the wires to the end of the new sensors (the sensor end), and wrap the connection with tape. Ensure the connection is smooth and strong enough to be pulled through cable channels without snagging or separating.

- Pull New Sensors Wire: Gently pull the old sensors wire out, guiding the new sensors wire along the same path through the rear compartment to the chamber. Pull slowly and steadily. If you encounter resistance, check for snags. Removing cable channel covers temporarily can aid in guiding the wire.

Tip: Avoid excessive force, which could damage the new sensor's wiring.

- Disconnect Old Sensors: Once routed, remove the tape and separate the old sensors.

- Connect New Sensor: Plug the new connector directly into the appropriate socket on the mainboard.

¶ 3.4.4 Install New Sensor(s) and Holders

- Prepare Holders: Take the new printed Sensor Holders (or reuse the old ones if undamaged and new ones are unavailable).

- Install Holders:

- Feed the new sensor wire through the hole in the printer chassis/wall from the rear compartment into the build chamber.

- From outside the chamber, align the new printed holder with the hole. Ensure the sensor wire sits correctly in the groove provided in the holder design.

- Using the Hammer and Punch Tool (or by hand pressure if possible), gently tap or press the holder firmly into the chassis hole until it is seated securely.

- Mount Sensors: Carefully clip or slide the new sensor tip into its designated place on the newly installed holder. Gently pull any excess wire slack back towards the rear compartment.

¶ 3.4.5 Reassembly and Testing

- Secure Wiring: Neatly route the new sensor cables in the rear compartment and secure with new Zip Ties.

- Final Checks: Close the rear access doors and the main printer door. Plug in the power cord.

- Test Sensors: Power on the printer. Check the displayed chamber temperature reading on the any tab. It should show a plausible room temperature. Optionally, heat the chamber slightly (e.g.,

40°C) and verify the reading increases accordingly.

¶ 3.5 Troubleshooting & FAQs

- **Q: Chamber temperature reads

-200°CorLowerafter replacement.- A: Check the sensor connection at the mainboard. Ensure it's fully seated in the correct port. Verify wires were inserted correctly into the connector housing if de-pinned. Inspect the wire for damage along its path.

- Q: Sensor holder broke during removal/installation.

- A: It is highly recommended to print replacement holders before starting. If unavailable, attempt a temporary secure mount, but obtain proper holders for long-term reliability. Download the STL file here.

- Q: Difficulty pulling the new wire through.

- A: Check for snags in the cable path. Temporarily remove cable channel covers for better visibility and manual guidance. Ensure the taped connection between old and new wires is smooth and slim.

¶ 3.6 Conclusion & Additional Resources

The chamber ambient temperature sensors have been successfully replaced. This ensures accurate monitoring of the build environment conditions.