¶ Z-Axis Motors Alignment Procedure

Misalignment of one or more Z-axis lead screws can cause the build plate to become stuck at the bottom of its travel, often accompanied by a grinding sound when the motor tries to move. However, be aware that a non-moving motor without grinding could also mean a driver issue or an electrical failure.

¶ Symptoms

-

Build Plate Stuck at the Bottom

- You try to raise the build plate from the bottom position and hear a grinding sound, but the plate (often the middle rear lead screw) doesn’t move.

- This usually indicates the motor is trying to spin, but the lead screw is misaligned with its linear rail.

-

No Grinding Sound

- If you do not hear any grinding or spinning noises at all, it may be a motor driver or electrical issue rather than a mechanical jam.

-

Stuck Above the Bottom Third

- If the lead screw jams when the bed is already raised (beyond about one-third of its travel), the cause might be a lubrication or maintenance issue rather than alignment.

- In such cases, carefully clean old grease with isopropyl alcohol (IPA), reapply fresh grease, and check if alignment is still needed.

¶ Tools Needed

- 2 mm Hex Driver/Wrench

¶ Preliminary Steps

-

Allow Movement Without Homing

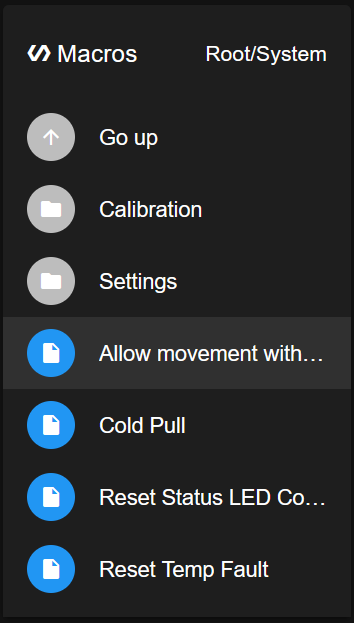

- On your printer’s Web Interface go to the

Dashboardtab, inMacrossection navigate to theSystemfolder and choose theAllow Movement Without Homingmacro.

- This lets you jog the Z-axis in small increments without a homing sequence.

- On your printer’s Web Interface go to the

-

Manually Help the Build Plate

- Open the printer door safely and carefully place your hand (Caution: HOT surfaces) under or on top of the build plate.

- Jog the bed upward in small increments (e.g., -25 mm) while gently guiding or lifting the corner that is stuck.

- Once the jammed lead screw loosens, the plate should move more freely on its own.

¶ Alignment Procedure

-

Loosen Motor Mounting Screws

- Use a 2 mm hex driver.

- After raising the bed to a more accessible height, locate the four screws at the bottom of each lead screw motor.

- Loosen each screw about half a turn to allow the motor to shift slightly if needed.

- Do not remove the screws entirely—just loosen enough that the motor can move.

-

Adjust the Bed

- Lower the bed all the way down via the Duet web interface or control panel (jog the Z-axis in positive increments).

- If the motor was stuck before, ensure it can now move smoothly without grinding.

- This fully extends the lead screw and helps align it with the linear rail.

-

Tighten the Screws

- With the bed fully lowered, tighten the screws one by one, starting with those you can access easily.

- If needed, raise the bed slightly to reach any remaining screws.

- This process should realign the lead screw with the linear rail and eliminate the jamming.

-

Test the Z-Axis

- Move the Z-axis up and down several times.

- Listen for abnormal noises or grinding.

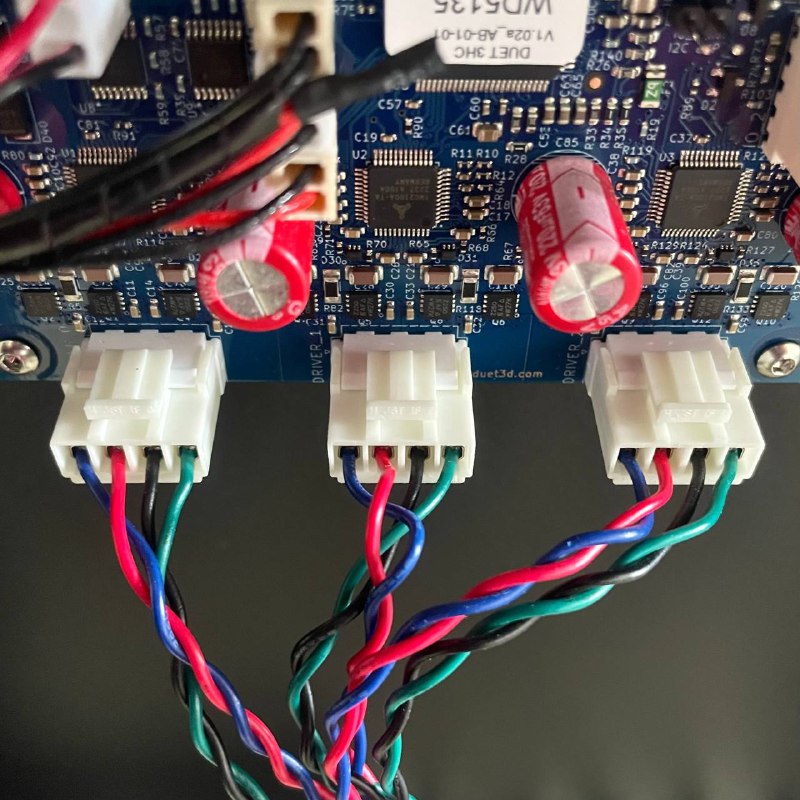

- If issues persist, verify lubrication on the lead screws, check the motor connector on the Expansion Board, or repeat alignment if necessary.

¶ Additional Considerations

- Driver or Electrical Issue: If the motor produces no sound and does not move at all, the problem could be in the stepper driver, wiring, or power supply.

- Lubrication & Maintenance: If the bed jams mid-travel (above the bottom third), remove old grease carefully with IPA, reapply fresh grease, and then repeat alignment steps as needed.

¶ Conclusion

Aligning the Z-axis motors is usually straightforward if the symptom is mechanical jamming (grinding sound with no movement). However, always confirm you do not have an electrical or lubrication issue first:

- Ensure the motor is actually spinning (or trying to spin).

- Clean and re-lubricate the lead screws if the bed is stuck higher up.

- Re-test movement after alignment to confirm the issue is resolved.

If problems persist after these steps—especially if the motor never spins or you suspect a driver fault—contact technical support for further guidance.