¶ Video Guide

¶ 3D Printer Tool Head Maintenance & Troubleshooting

This guide provides a comprehensive overview of how to remove, disassemble, maintain, and reassemble your 3D printer’s tool head (hotend/extruder assembly). It consolidates multiple references, including hotend installation/removal procedures, nozzle changes, heater/sensor replacements, and proper grounding wire handling, ensuring you have a clear step-by-step process.

¶ Introduction

A properly maintained tool head is crucial for consistent print quality. Over time, filament residue, clogs, or worn-out components can cause print failures. This guide walks you through:

- Removing filament and the nozzle safely

- Handling the grounding wire and preventing electrical issues

- Disassembling the hotend for inspection/cleaning

- Replacing or servicing parts (e.g., heat break, sensor, heater)

- Reassembling and wiring the tool head correctly

- Common troubleshooting tips for clogs or misalignment

Important: Certain steps require heating the hotend to high temperatures (up to 400°C). Always follow safety guidelines to avoid burns or electric shocks.

¶ Tools & Materials

- Wrenches:

- 7 mm (or 9/32") for nozzle removal

- 12 mm or adjustable wrench for holding the heat block

- 2 mm Hex Driver (commonly used for fan shroud/extruder and grounding wire screws)

- Pliers or Adjustable Wrench (to hold the heat block during nozzle changes)

- Boron Nitride/Thermal Paste (for the heater, sensor, nozzle, heat break)

- Spare Components (optional):

- Nozzle

- Heat break

- Heater cartridge

- Temperature sensor (PT1000)

- PTFE tube

- Protective Equipment:

- Heat-resistant gloves

- Safety glasses

Reference Documents/Links:

¶ Safety & Pre-checks

- Hot Surfaces: Before handling the nozzle or heat block, ensure they are heated to soften filament but use heat-protective gloves. Afterward, allow all components to cool before fully disassembling.

- Power Off: Once you finish removing the nozzle and filament while hot, switch the printer off and unplug the power cable prior to disconnecting wires or removing major components.

- Wiring Polarity: When removing or reinstalling wires, note their positions (take photos) to avoid incorrect polarity, which can damage the heater or sensor.

- Grounding Wire: Your hotend may have a dedicated grounding wire (often green or yellow/green). Always disconnect and reconnect it properly to prevent electrical issues.

¶ Step-by-Step Instructions

¶ 1. Removing Filament

- Preheat the hotend to the filament’s printing temperature.

- Unload the filament:

- Automated: Use the printer’s unload filament feature (if supported).

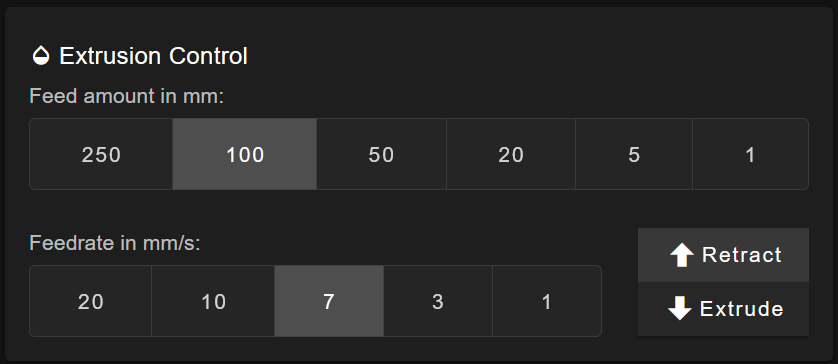

- Manual: In the web interface (Dashboard), click Retract (100 mm at ~7 mm/s), or use the extruder’s lever to pull the filament out by hand.

- Reference: If unsure, see the Filament Loading/Unloading.

Tip: Always remove filament while the hotend is hot. Molten plastic will help prevent clogging or filament residue in the nozzle and heat break.

¶ 2. Removing the Nozzle (While Hot)

- Heat the hotend to printing temperature (or slightly lower, e.g., 20–30°C below standard printing temp).

- Secure the heat block with pliers or an adjustable wrench.

- Unscrew the nozzle clockwise (looking up from the nozzle tip) using a 7 mm wrench.

- Caution: The metal components will be extremely hot. Wear heat-resistant gloves and avoid contact with any heated surfaces.

- Cool Down: After nozzle removal, power off and allow everything to cool to a safe handling temperature.

Why Hot?: Removing the nozzle hot prevents hardened filament from binding the threads. This reduces the risk of damaging the heat block or nozzle.

Additional Reference: For further details on nozzle removal or installation, see Nozzle Change.

¶ 3. Power Off & Disconnect Wires

-

Power Off

- Power off the printer by unplugging it from the wall to ensure complete electronic safety.

-

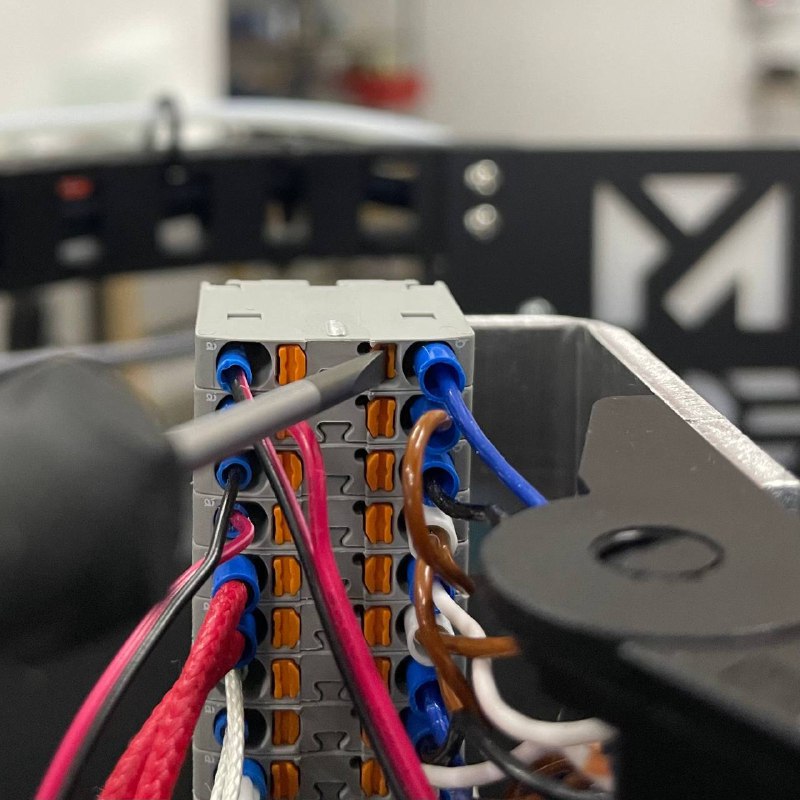

Remove Distribution Block Connections

Tip: Take a photo or label wires beforehand to track polarity and connections.

- Gently unplug the heater, thermistor/temperature sensor, grounding wire, and any other hotend-related wires.

- How to Disconnect:

- Using a 2 mm hex screwdriver, press down on the orange spring-loaded tab inside the distribution block opposite to the wire you want to remove.

- Support the distribution block from the back to prevent applying excessive force on the tool head.

- When the tab is fully pressed, gently pull the wire straight out.

- Do not force the wire out, as this can cause damage.

- Using a 2 mm hex screwdriver, press down on the orange spring-loaded tab inside the distribution block opposite to the wire you want to remove.

- Reference: Wiring Schematic

¶ 4. Removing Fan Shroud & Wire Guard

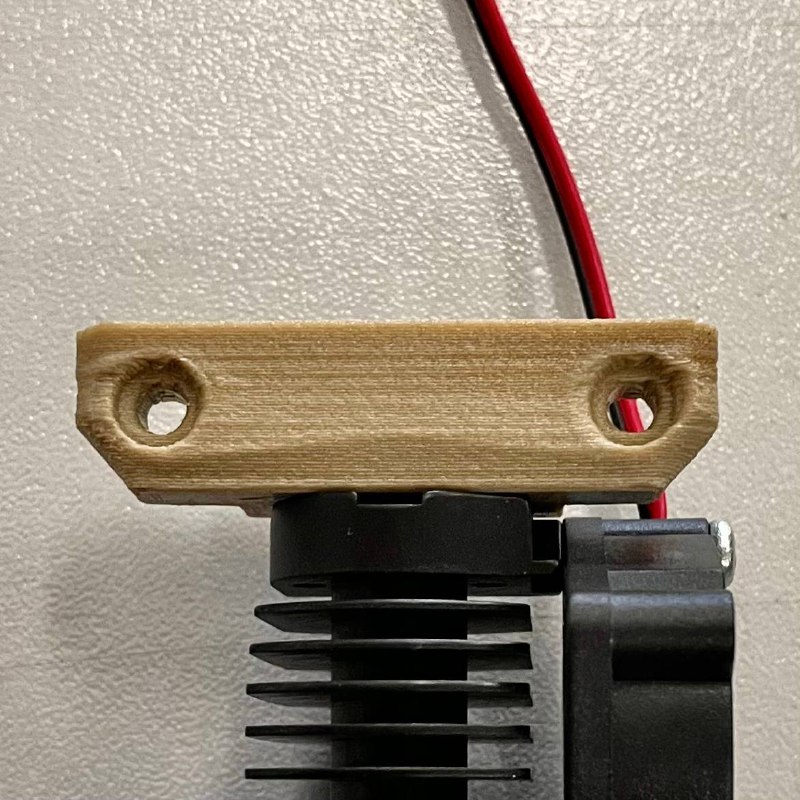

- Remove Fan Shroud:

- Use a 2 mm hex driver to remove the two screws holding the fan shroud in place.

- Slide off the shroud and carefully set it aside with the fan (if still attached).

- Use a 2 mm hex driver to remove the two screws holding the fan shroud in place.

- Remove Wire Guard:

- Remove any wire cover to fully access the extruder/hotend area.

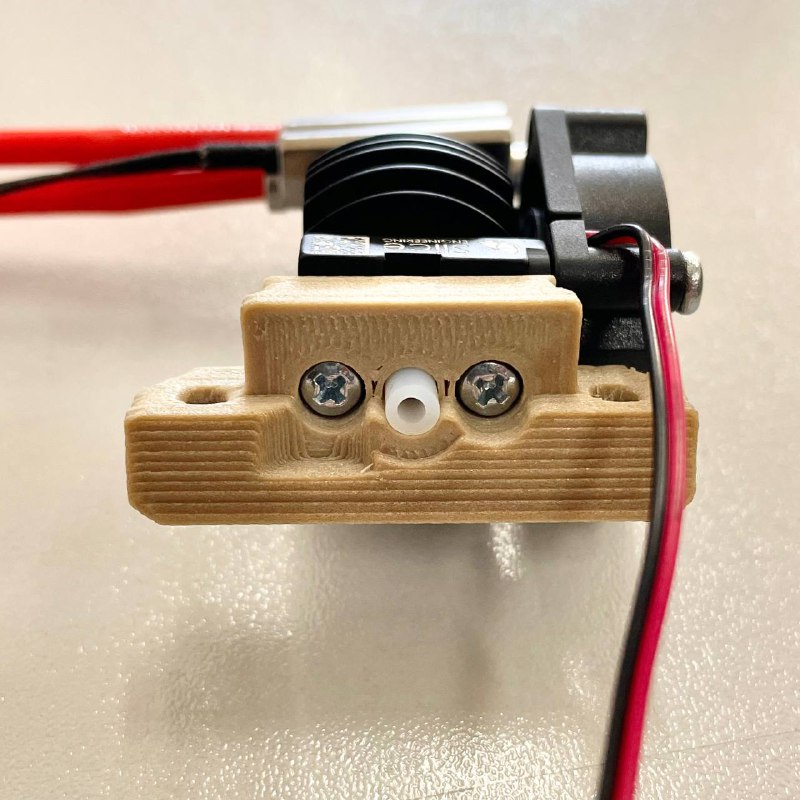

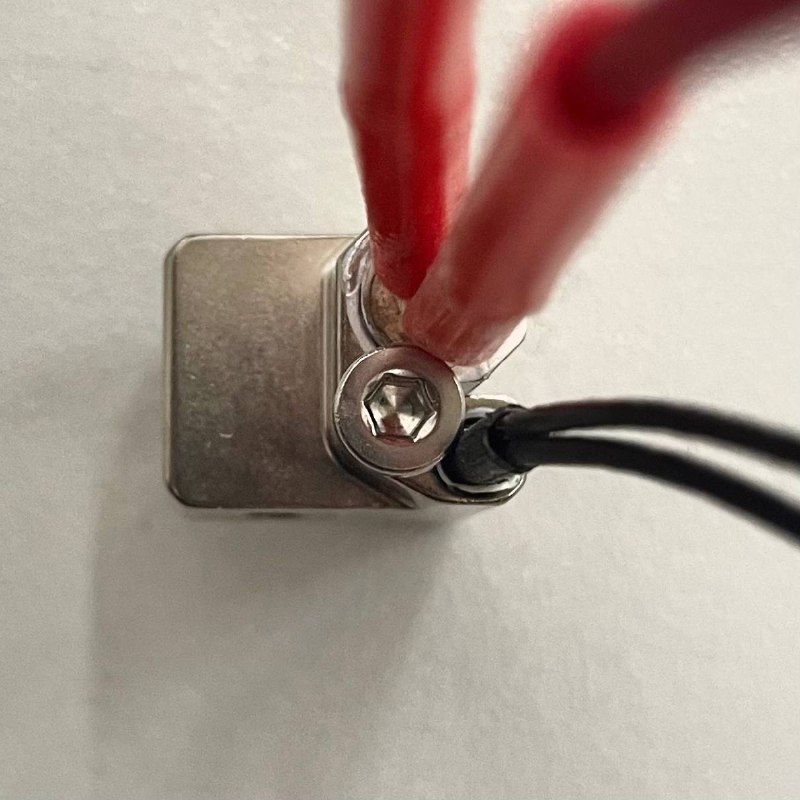

¶ 5. Remove Grounding Wire (Lug Style Crimp)

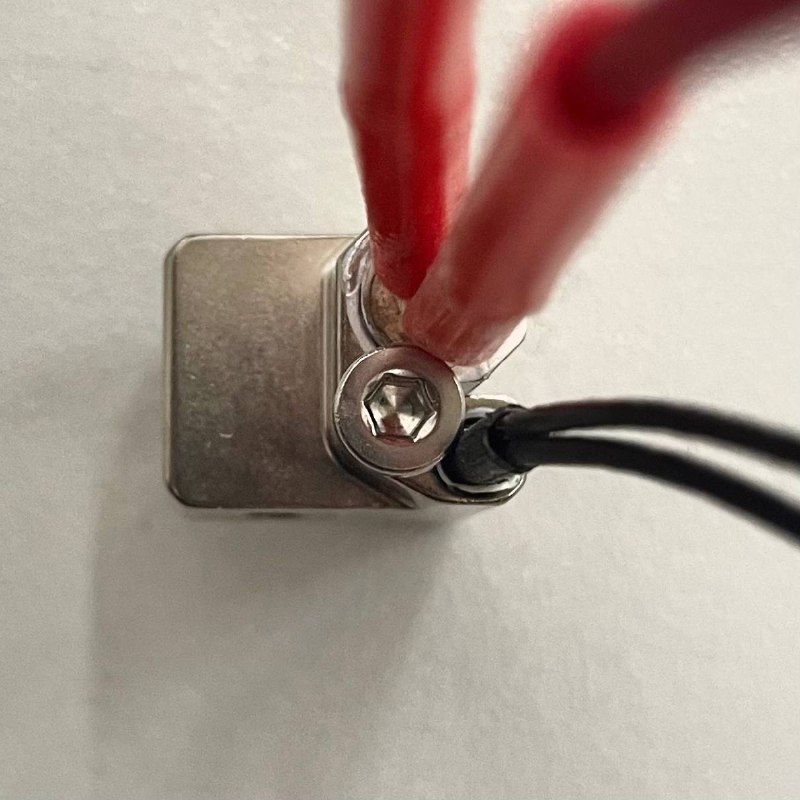

Before proceeding to remove the hotend assembly, you must disconnect the grounding wire at the hotend.

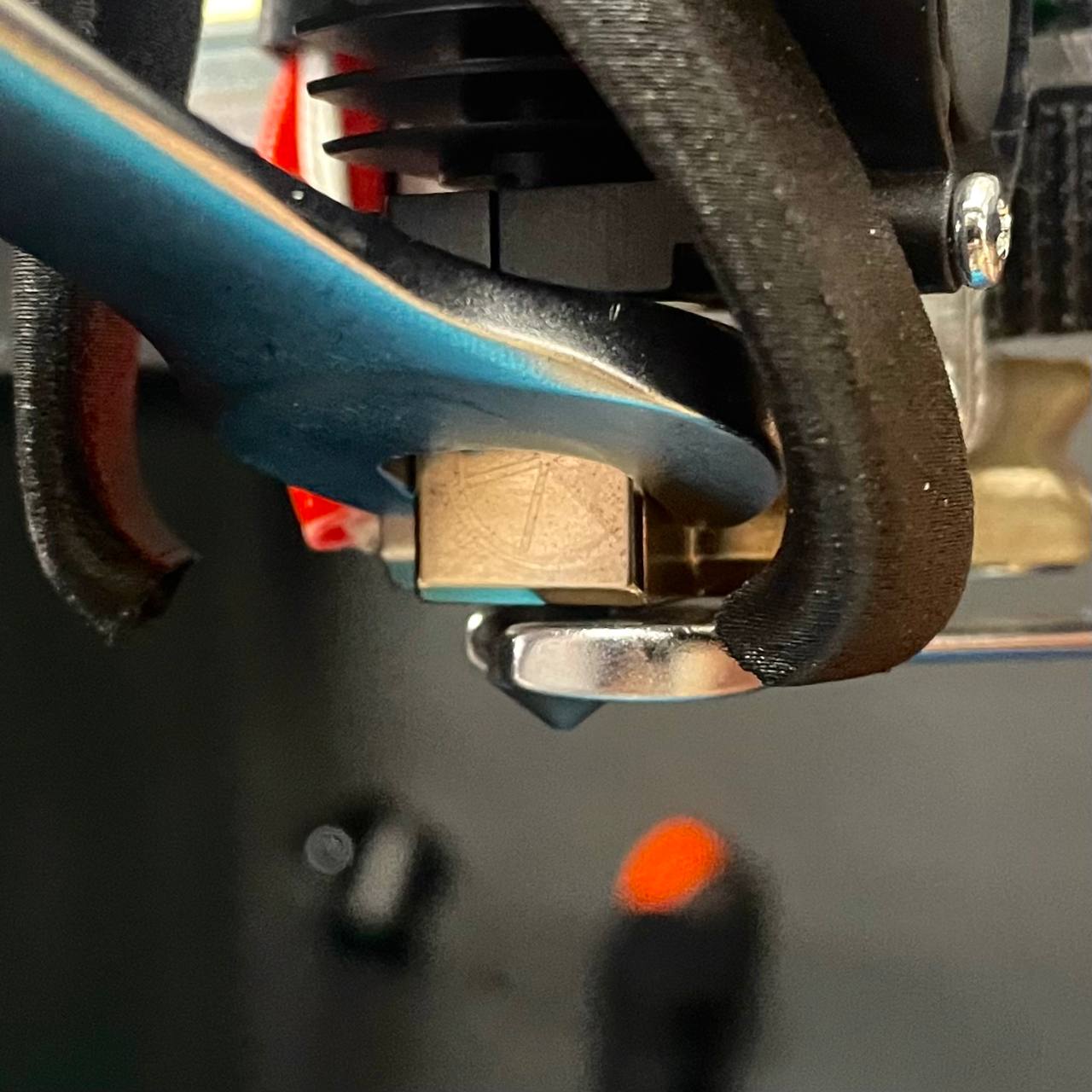

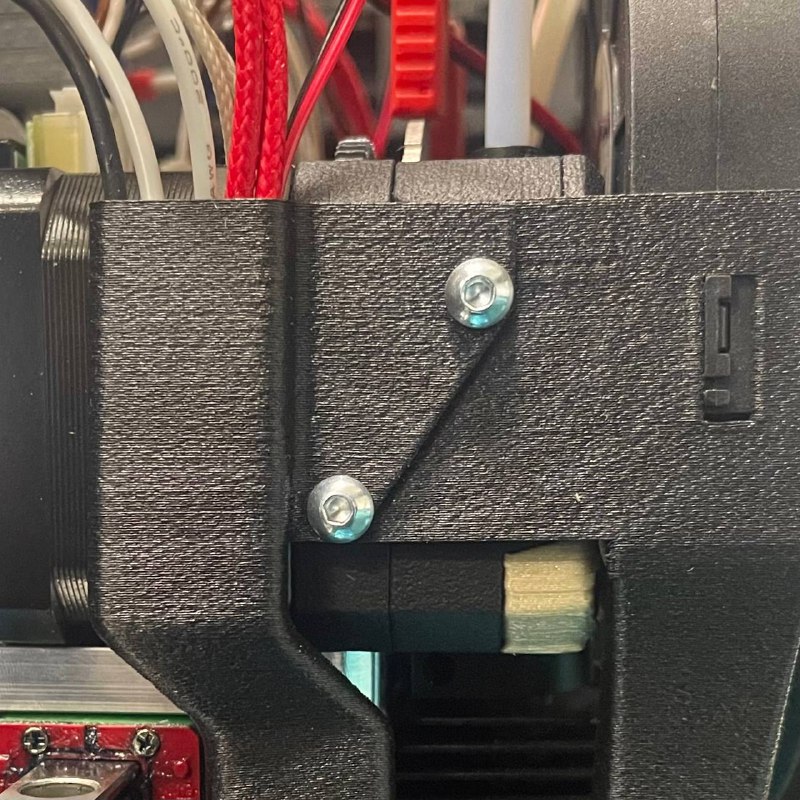

- Locate the lug-style crimp attached to the hotend body (see picture below).

- Using a 2 mm hex screwdriver, remove the screw holding the lug in place.

- Carefully set the grounding wire and lug aside for later reinstallation.

Important: This wire is essential for proper grounding. Ensure it only contacts the hotend metal surface to avoid electrical issues.

¶ 6. Removing the Hotend Assembly

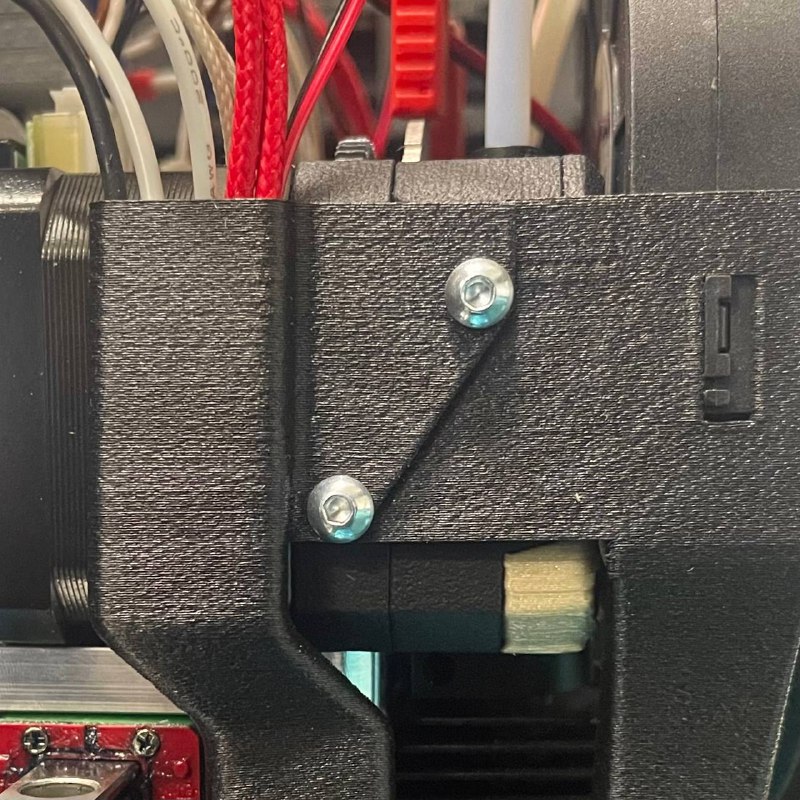

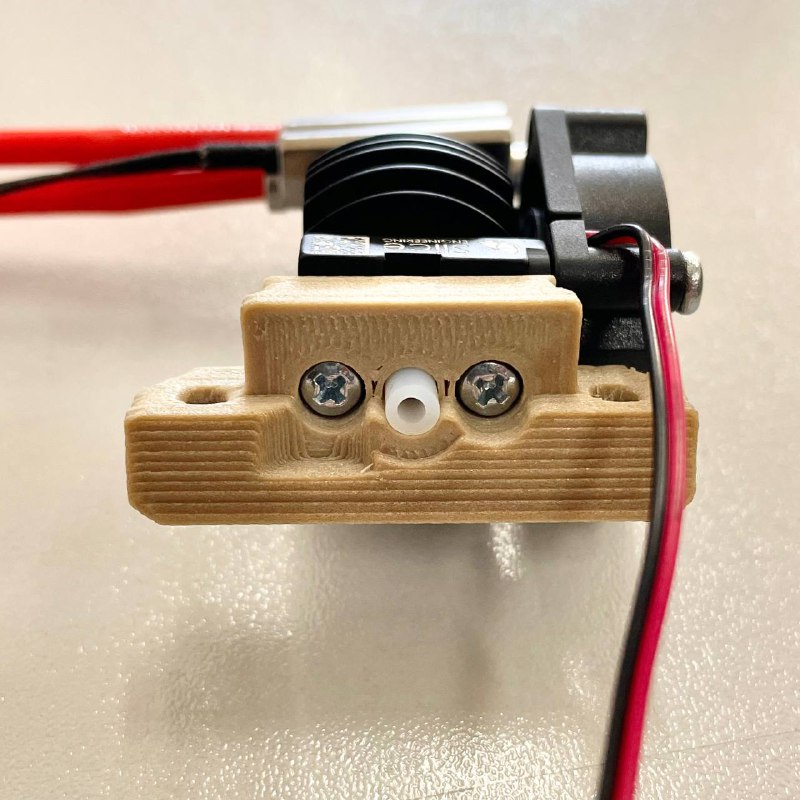

- Extruder Front Plate:

- Using a 2 mm hex driver, remove or loosen the front plate screws on the extruder (often 2 screws).

- Using a 2 mm hex driver, remove or loosen the front plate screws on the extruder (often 2 screws).

- Slide Out the Hotend:

- Pull the hotend toward you (forward).

- If the hotend doesn't slide out easily, gently shake it from side to side while pulling it towards you.

- Check for stray filament or debris that might prevent smooth removal.

¶ 7. Disassembling the Hotend

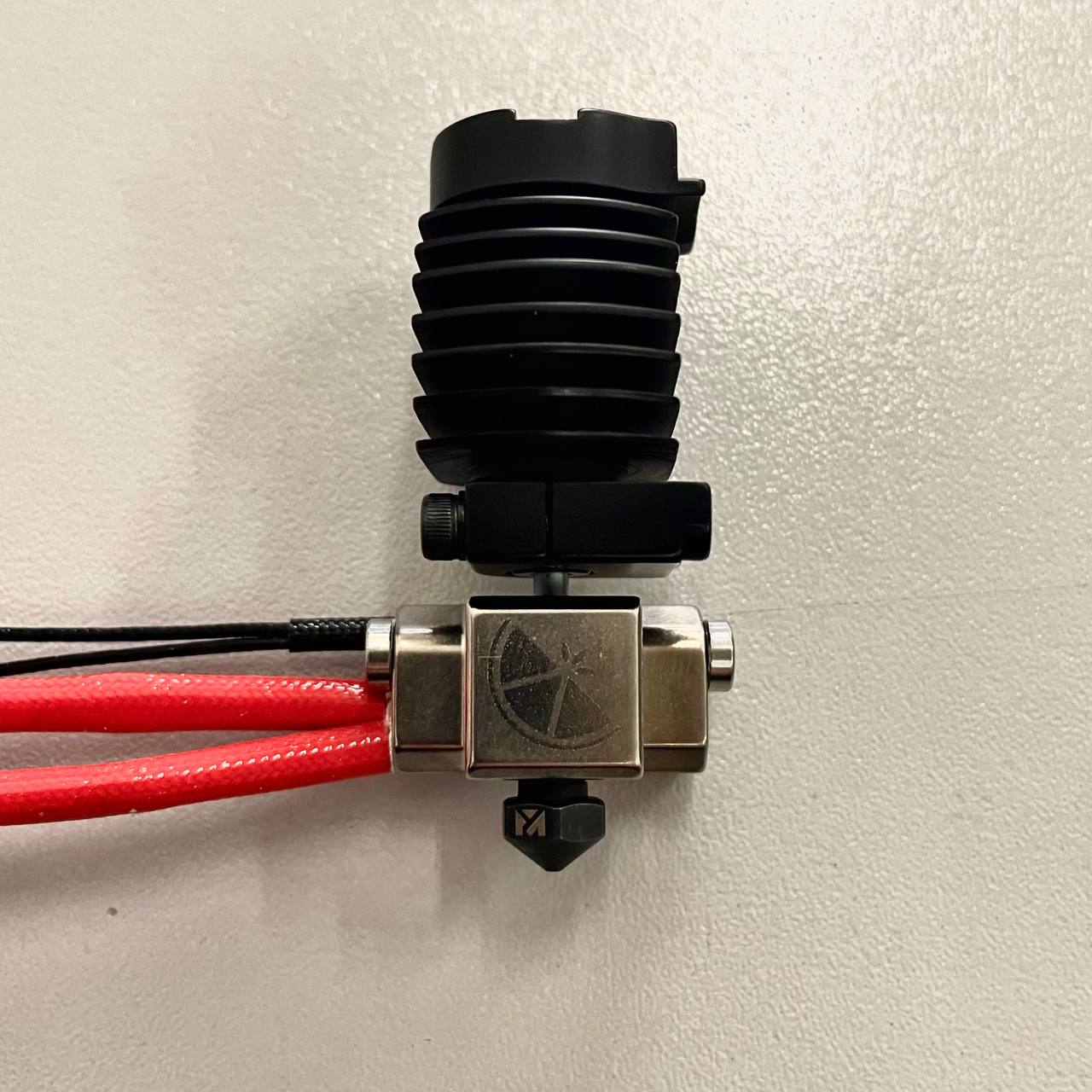

Once the hotend is free from the extruder, you can break it down into its core parts:

- 3D Printed Interface/Adapter:

- Remove the top interface plate that mates the hotend to the extruder.

- Remove the top interface plate that mates the hotend to the extruder.

- PTFE Tube:

- Inspect the PTFE tube inside the radiator. Confirm it’s flush and cut to correct length.

- Replace if damaged or too short.

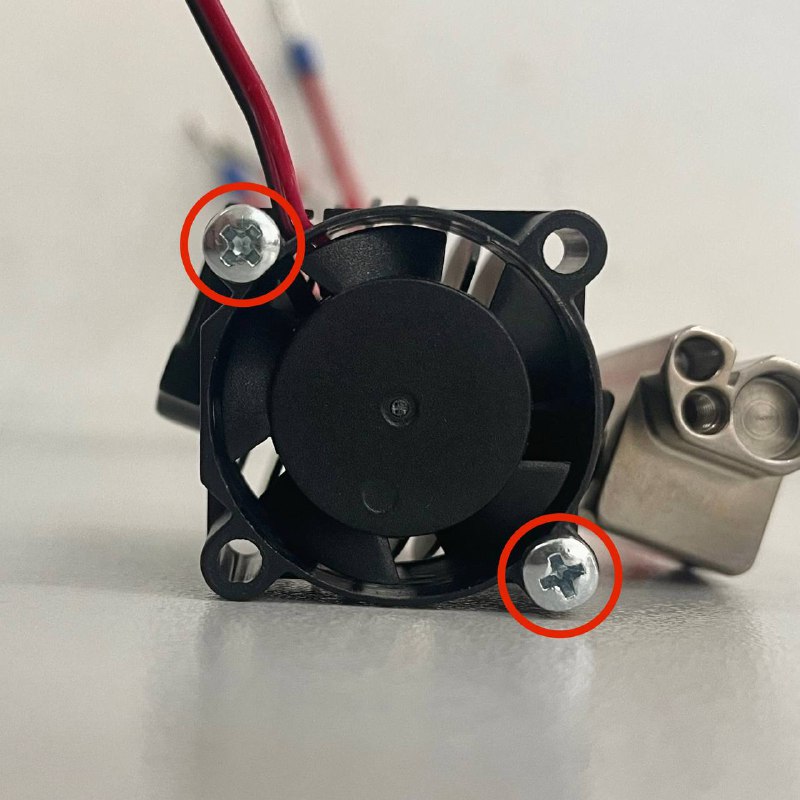

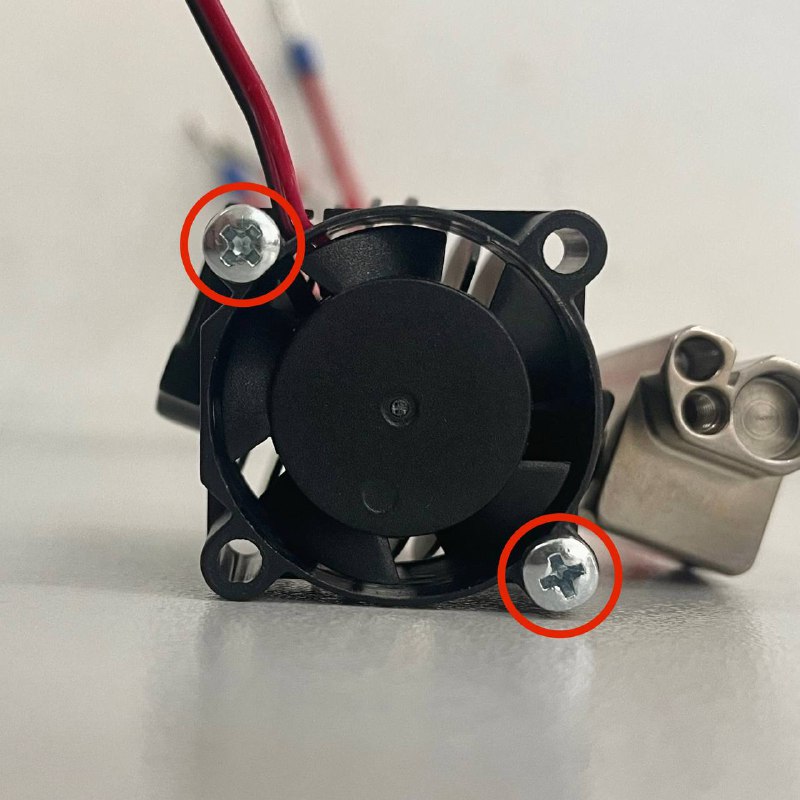

- Cooling Fan:

- Unscrew 2 screws and remove the fan.

- Unscrew 2 screws and remove the fan.

- Radiator:

- Loosen the screw on the radiator and remove it.

- Loosen the screw on the radiator and remove it.

- Heat Break:

- Unscrew the Heat Break.

- Unscrew the Heat Break.

- Heater Cartridge & Temperature Sensor:

- Remove heater cartridge and temperature sensor by loosening the set screws.

- Gently slide these out if they need replacement or inspection. They’re often secured by small set screws.

- Remove heater cartridge and temperature sensor by loosening the set screws.

Inspection:

- Grounding Wire: Check if the grounding wire is worn out, burned, or excessively bent due to heat exposure. Replace if damaged.

- Fan Wires, Sensor Wires, Heater Wires: Ensure no fraying, burning, or other damage.

- Tip: Apply Boron Nitride/Thermal Paste to threads and surfaces (nozzle, heat break, sensor, heater) as needed for heat conduction and easier future removal.

¶ 8. Reassembling the Hotend

Reverse the disassembly steps:

- Install or Replace the Temperature Sensor & Heater:

- Lightly coat each component with thermal paste.

- Slide them into the heat block.

- Secure with the set screw (do not overtighten).

- Attach the Heat Break:

- Thread the heat break into the heat block finger-tight. Avoid applying torque to the thin heat break walls.

- If using a Copperhead™ or similar, refer to the manufacturer’s instructions for correct orientation/fit.

- Reattach the Radiator:

- Slide the heat break into the radiator.

- Tighten the set screw carefully.

- Slide the heat break into the radiator.

- Reattach the Cooling Fan:

- Attach the fan to the radiator.

- Attach the fan to the radiator.

- Reattach 3D Printed Interface Plate and PTFE Tube:

- Attach the interface plate to the radiator.

- Reinsert PTFE tube. Ensure correct length and flush fit. This prevents gaps that cause clogs.

Additional Reference: For more details on sensor and heater installation or wiring inspection, see Hotend Temp Sensor & Heater Maintenance.

¶ 9. Reinstalling the Hotend Assembly

- Slide the Hotend back into the extruder grooves.

- Secure it with the original screws on the front plate.

- Reconnect the Grounding Wire:

- Fasten the grounding wire to the hotend body using the 2 mm hex driver.

- Fasten the grounding wire to the hotend body using the 2 mm hex driver.

Important: This wire must not touch any other metal components except the hotend itself. If it does, Zipro (ground detection) may fail, and you risk damaging your printer.

- Reconnect Other Wires:

- Follow your reference photo or wiring diagram for heater and sensor polarity.

- Reinstall Fan Shroud & Wire Guard:

- Replace the fan shroud using the 2 mm hex screws.

- Make sure wires, including the grounding wire, are tucked properly under the wire guard without excessive bending or contact with other metal parts.

¶ 10. Final Steps & Nozzle Installation

- Initial Tightening:

- Thread the nozzle in counter-clockwise (from the bottom) by hand or at ~1 Nm torque.

- Hold the heat block with a wrench to avoid twisting the heat break.

- Heat Soak:

- Heat the hotend to your normal printing temperature.

- Let it sit for a few minutes to ensure all components expand and seat properly.

- Final Tightening:

- Once hot, use your wrench again to slightly re-tighten the nozzle (still around 1–1.5 Nm max).

- This helps prevent leaks around the threads.

- Perform a Test Extrusion:

- Load filament to confirm a clear path and ensure no jams or leaks at the nozzle.

Note: For a detailed walkthrough of nozzle changes, see Nozzle Change.

- Perform a Calibration:

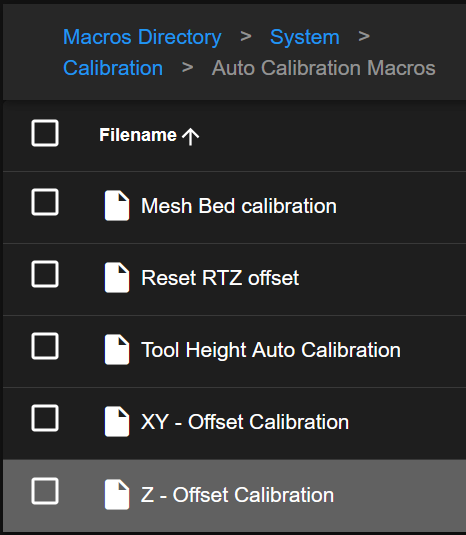

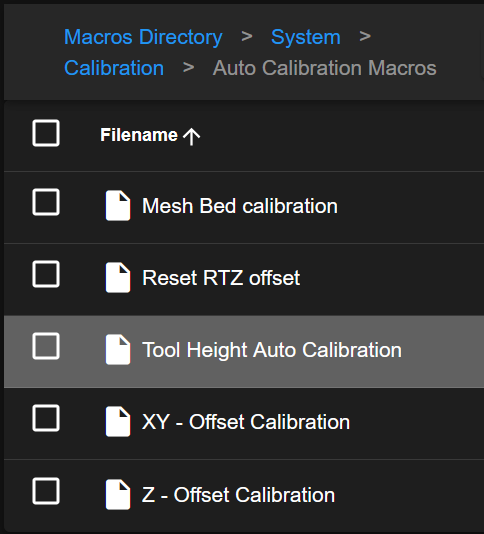

- In the web interface go to the

Macrostab and navigate toSystem > Calibration > Auto Calibration Macros. StartZ - Offset Calibrationand follow the instrucions on the screen.

- Start

Tool Height Auto Calibrationand follow the instructions on the screen.

- In the web interface go to the

¶ Troubleshooting Tips & FAQs

- Filament Won’t Retract:

- Ensure hotend is fully heated to the filament’s melting point.

- Try manual retraction with the extruder lever depressed.

- Nozzle Still Clogged:

- Remove the nozzle again and test extrusion without it.

- If the heat break is clogged, see Clearing Clogged Hotend/Unclogging.

- Poor Layer Adhesion/Under-Extrusion:

- Check for partial clogs or incorrect PTFE tube length.

- Confirm the nozzle is tightened and sealed properly after heat-soaking.

- Incorrect Temperature Readings:

- Verify sensor wires are connected to the correct terminals.

- Check for damaged thermistor or firmware settings.

- Heater Not Working:

- Check polarity and continuity of heater wires.

- Ensure you have the correct voltage (e.g., 24V) for your heater cartridge.

- Electrical Ground Issues:

- Inspect that the hotend grounding wire is securely fastened and only contacting the hotend metal surface.

¶ Conclusion

By following these steps, you can safely remove, disassemble, maintain, and reassemble your 3D printer’s tool head. Regular maintenance—including nozzle checks, cleaning the heat break, inspecting the grounding wire, and ensuring correct wiring connections—helps prevent clogs, print failures, and electrical hazards.