¶ Introduction

In this manual, we will cover:

- What causes heater faults in the 22 IDEX 3D printer.

- How temperature sensors work and why sudden spikes or drops occur.

- Common scenarios (and their symptoms) that trigger heater faults.

- Step-by-step instructions to diagnose, fix, and prevent heater faults.

- Best practices for stable temperature readings and overall maintenance.

Heater faults are protective mechanisms built into the printer’s firmware to help prevent damage or fire hazards. When the printer’s control system detects abnormal or unexpected temperature behavior—such as a spike, drop, or slow heat-up—it will trigger a fault and shut off the heater.

¶ Tools & Materials

Before starting any troubleshooting or maintenance, make sure you have the following:

- Replacement Temperature Sensor

- For hotend, bed, chamber heater or chamber.

- Thermal Conductive Paste

- Ensures optimal thermal contact when installing a new sensor. (e.g., Boron Nitride paste)

- 2 mm Hex Screwdriver or Allen Key

- For accessing certain panels or sensor mounts.

- Protective Gloves

- For handling hot components and avoiding burns.

- Reference Materials

Safety Warning: Always power off and unplug your 3D printer before removing covers, checking wiring, or replacing parts.

¶ How the Temperature Sensor Works

-

Basic Principle

- The printer’s temperature sensor changes its electrical resistance in response to temperature changes.

- The printer’s firmware measures this resistance and converts it into a temperature reading in Celsius.

-

Firmware Monitoring

- The control system continuously checks if the temperature increase or decrease matches predicted values.

- If the system detects a sudden spike or drop, or a slow rise in temperature during heat-up, it may trigger a heater fault to protect the machine.

¶ Common Heater Fault Scenarios

Below are the main scenarios that can trigger a heater fault, along with their typical symptoms, possible causes, and recommended fixes.

¶ 1. Temperature Spikes Up

- Symptom: The printer’s temperature graph shows abrupt upward spikes (potentially reading up to 2000°C).

- Possible Cause:

- Poor connectivity or a loose/disconnected wire in the temperature sensor circuit.

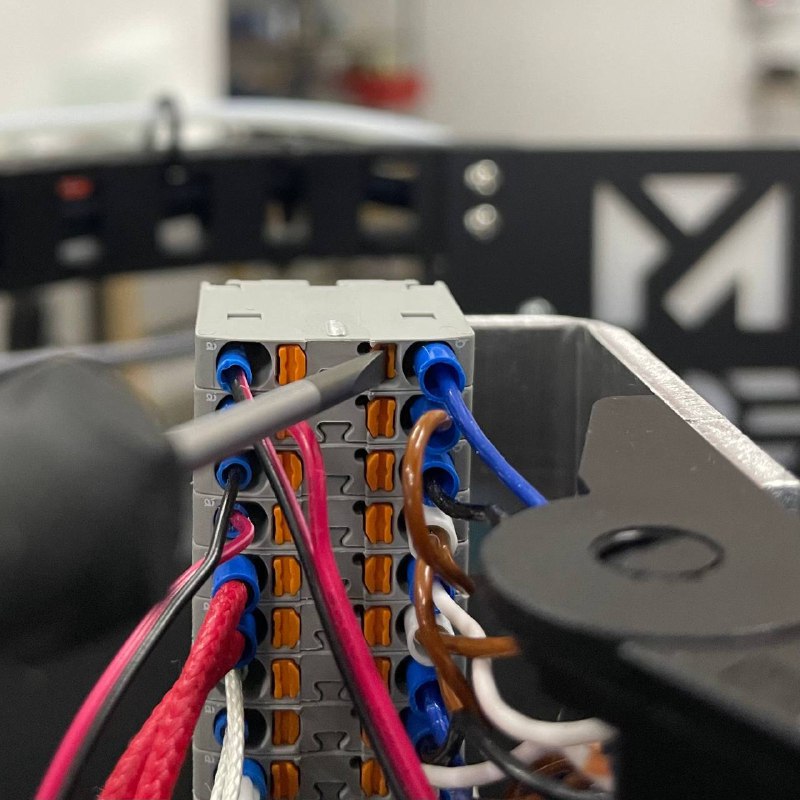

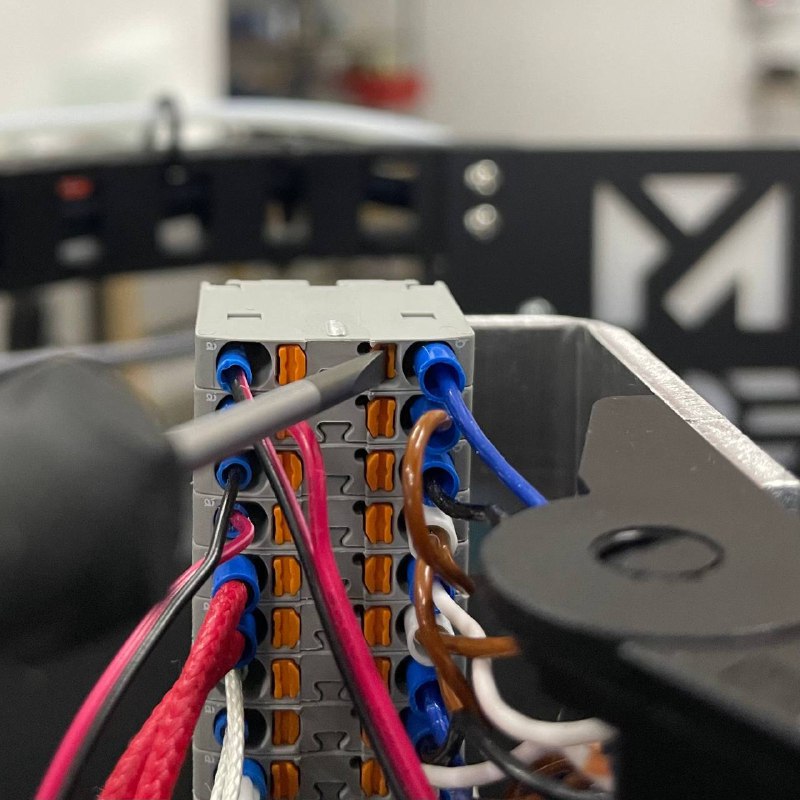

- Damaged or improperly seated wiring inside the distribution block.

- Diagnostic Steps:

- Power off the printer.

- Check and reseat wiring connections in the distribution block:

- Press the orange tab to release the wire.

- Inspect the wire ends and crimps for damage.

- Reinsert securely.

- Press the orange tab to release the wire.

- If spikes persist, replace the temperature sensor.

¶ 2. Temperature Spikes Down

- Symptom: The temperature suddenly drops on the graph (potentially down to -273°C).

- Possible Cause:

- A short circuit in the sensor wiring (worn insulation causing wire-to-wire contact).

- Severely damaged or frayed sensor cables.

- Diagnostic Steps:

- Power off the printer.

- Inspect the temperature sensor wire thoroughly for cuts or exposed metal.

- If damaged, replace the temperature sensor.

- Check the heater wires on the tool head as well; any fraying must be addressed to avoid mainboard damage.

¶ 3. Inadequate Heating Rate (Slow Heat-Up or Sudden Cooling)

- Symptom:

- The printer stops heating and displays a “temperature lower than expected” error.

- The temperature fails to rise fast enough or drops suddenly during printing.

- Possible Causes:

- Cold Surfaces on a Hot Bed

- Placing a cold build surface on a hot bed can rapidly cool the plate.

- Open Chamber

- Leaving the door open while heating to high temperatures (e.g., 200°C or more) can cause heat loss.

- Excessive Cooling Fan

- High airflow on the nozzle or build plate can drop the temperature below targets.

- Cold Surfaces on a Hot Bed

- Fixes:

- Close the printer door/lid when heating to maintain a stable chamber.

- Preheat or at least allow the build plate to partially reach its set temperature before placing a cold build surface.

- Reduce part cooling fan speed in your slicer or use a silicone sock to insulate the hotend.

¶ 4. Temperature Oscillation (Wavy Line on the Graph)

- Symptom:

- Instead of staying near the setpoint, the temperature line oscillates up and down in a wavelike pattern.

- Possible Cause:

- PID (Proportional-Integral-Derivative) control settings are off, causing the system to over- and under-shoot the target temperature.

- Fixes:

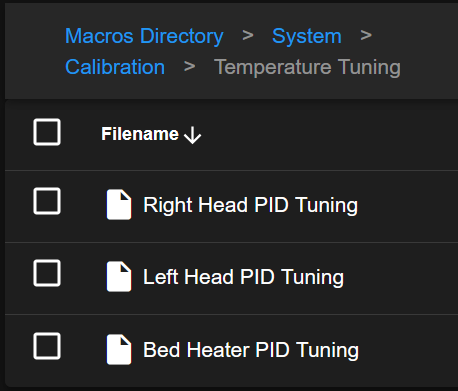

- Perform a PID Tuning:

- Go to

Macrostab. - Navigate to

System > Calibration > Temperature Tuning. - Choose the necessary macro.

- Go to

- Ensure the hotend or bed starts from ambient temperature for accurate tuning.

- Avoid leaving the printer unattended during calibration.

- Perform a PID Tuning:

¶ 5. Inaccurate Temperature Readings at Ambient

- Symptom:

- After the Machine is completely cooled to room temperature, and most temperature sensors read a similar ambient value, but one sensor reads significantly higher or lower than the others.

- Possible Cause:

- Higher-than-ambient reading (while physically cold to the touch): often indicates a loose contact or partially disconnected sensor.

- Lower-than-ambient or negative reading (while physically cold to the touch): often indicates a short circuit or frayed/damaged wires.

- Diagnostic Steps:

- Confirm the machine is cold:

- Use an IR temperature gun or carefully touch the component (bed or tool head).

- Be cautious: surfaces might be hot if the sensor is genuinely accurate.

- Check the suspect sensor:

- If it reads higher than ambient but is cold to the touch, inspect all wire connection points (e.g., distribution block, mainboard, or tool head wiring) for looseness. Reseat if necessary.

- If it reads noticeably lower or negative, look for wire damage or frayed insulation that could cause a short.

- Replace the sensor if wiring is damaged:

- A sensor that continues to read incorrectly after reseating or repairing connections may need to be replaced.

- Confirm the machine is cold:

¶ General Step-by-Step Troubleshooting

-

Check for External Factors

- Ensure the printer door is closed and fans are set appropriately.

- Remove any cold surface from a hot bed to prevent sudden temperature drops.

-

Inspect All Connections

- Power off the printer.

- Locate the distribution block for your tool head or build plate.

- Press the orange tab(s) to release each wire, inspect, and re-seat them firmly.

-

Replace the Temperature Sensor (If Needed)

- Power Off and unplug the printer.

- Disconnect the old sensor from the distribution block.

- Apply thermal conductive paste to the new sensor if required.

- Insert and secure the new sensor wires.

- Power on the printer and test for stable temperature readings.

- The replacement procedure for the Head Temperature Sensor is detailed separately here.

-

Perform a Test Heat-Up

- Heat the nozzle or build plate to a moderate temperature (e.g., 150–200°C).

- Observe the temperature graph for any unusual spikes or drops.

-

Run PID Calibration (Optional but Recommended)

- Use the printer’s built-in macro to recalibrate temperature control parameters.

- Ensure the hotend/bed is at ambient temperature before starting.

- PID Tuning Guide

¶ Conclusion & Additional Resources

Maintaining stable temperature readings is crucial for high-quality prints and overall printer safety. By understanding how the temperature sensor works and keeping an eye on external factors like fan cooling or open doors, you can avoid most heater faults. If you still encounter persistent errors after reseating wires and checking for damaged sensors, consider the following resources:

For additional support, contact our support team at support@visionminer.com